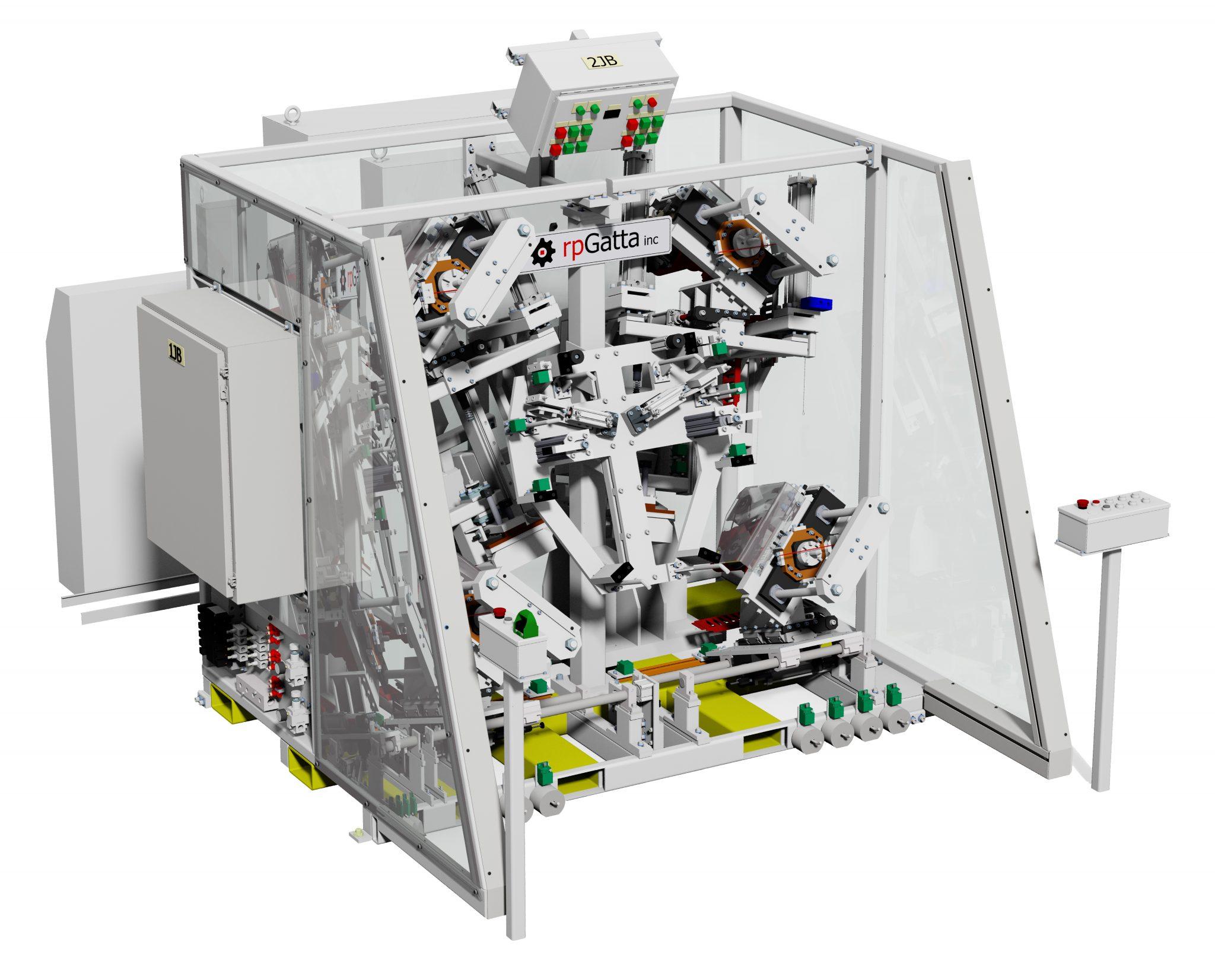

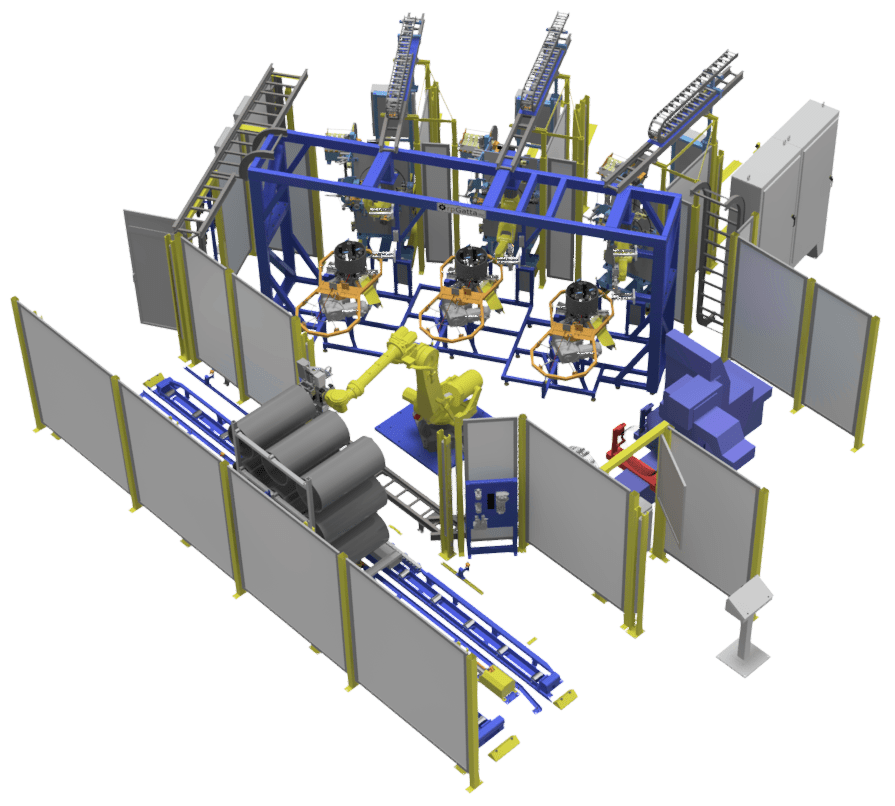

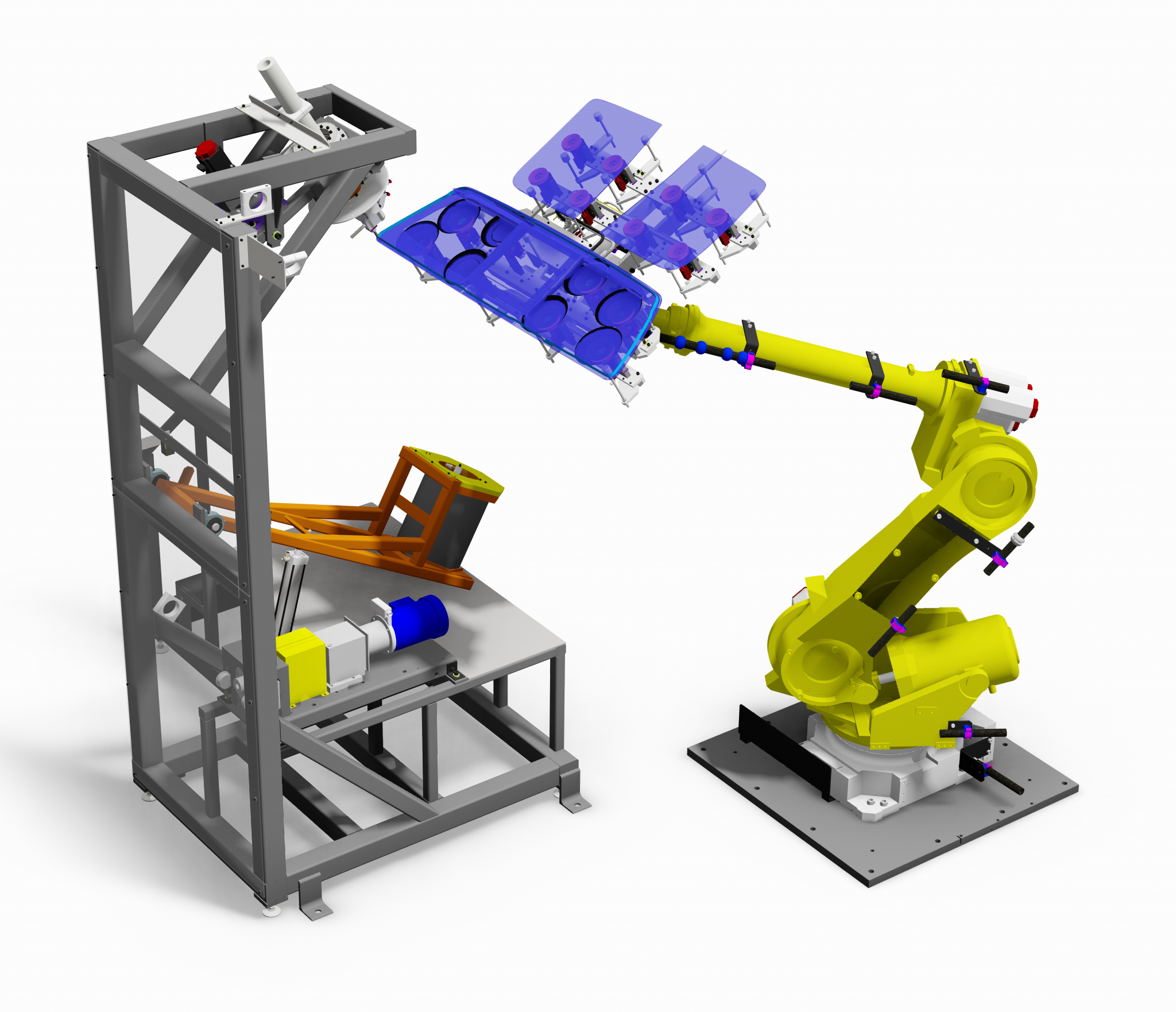

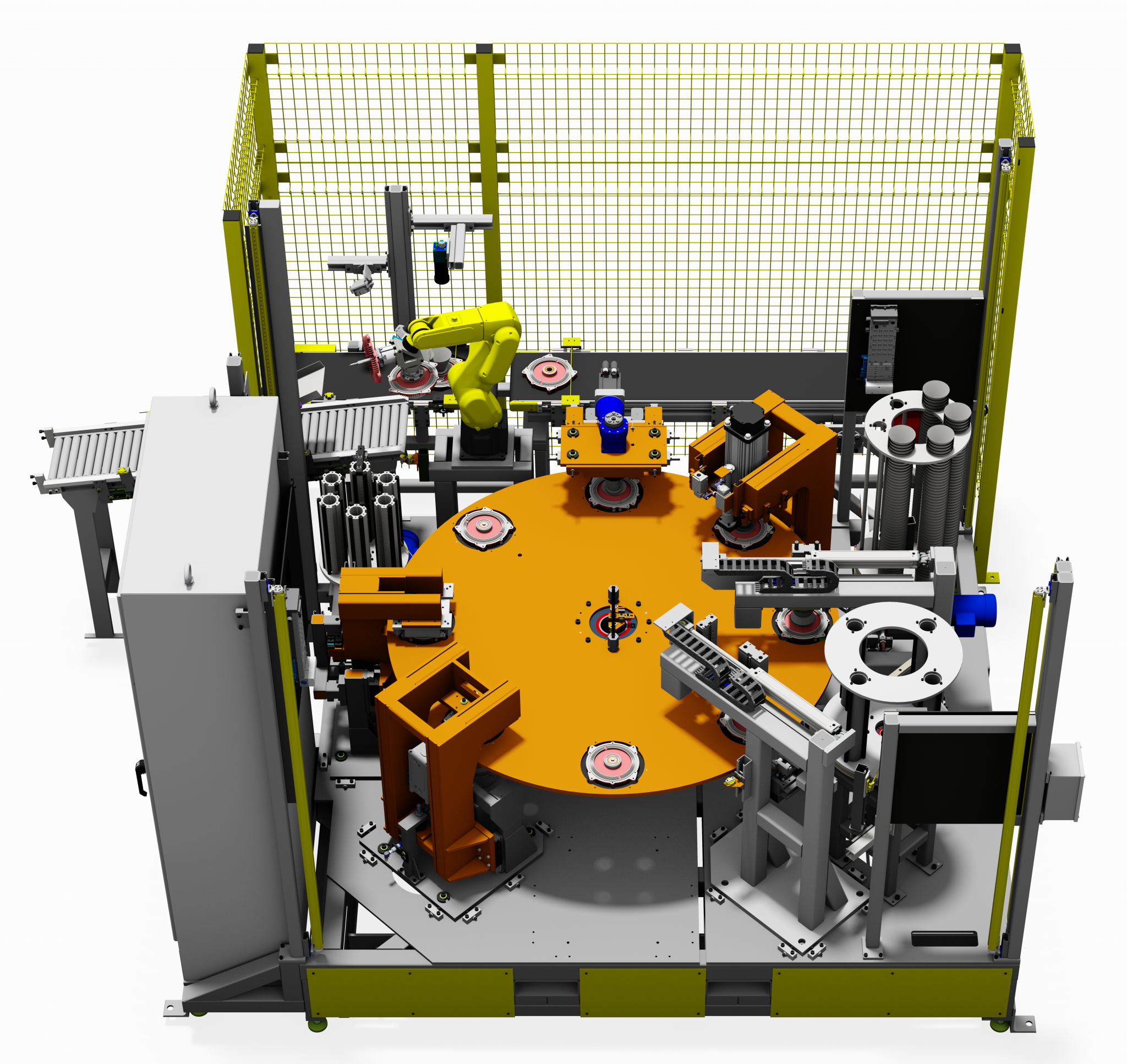

Capabilities Through Past Custom Projects

We do it all. There is no engineering challenge we will turn down.

In general the more challenging the application the further we excel.

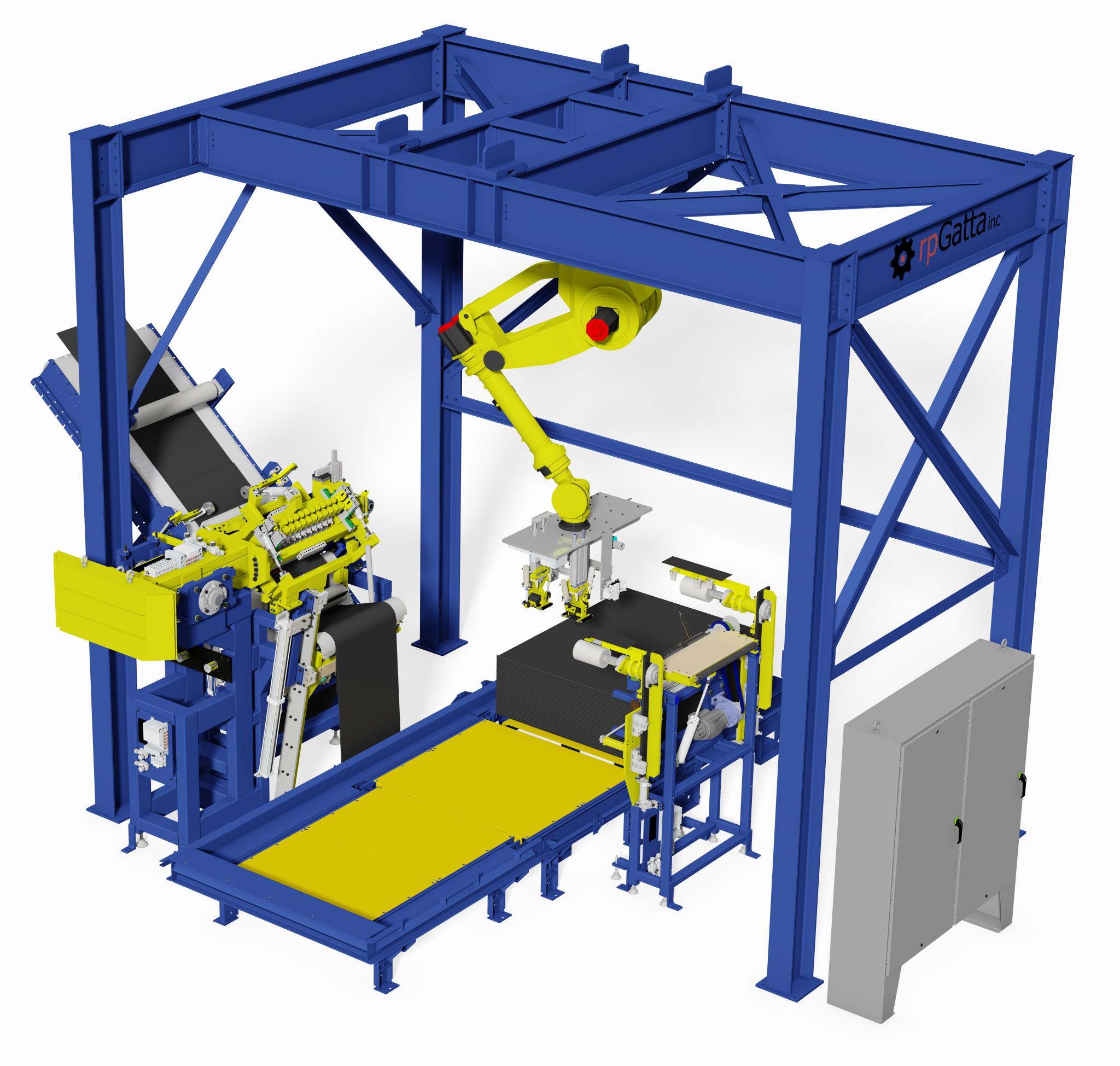

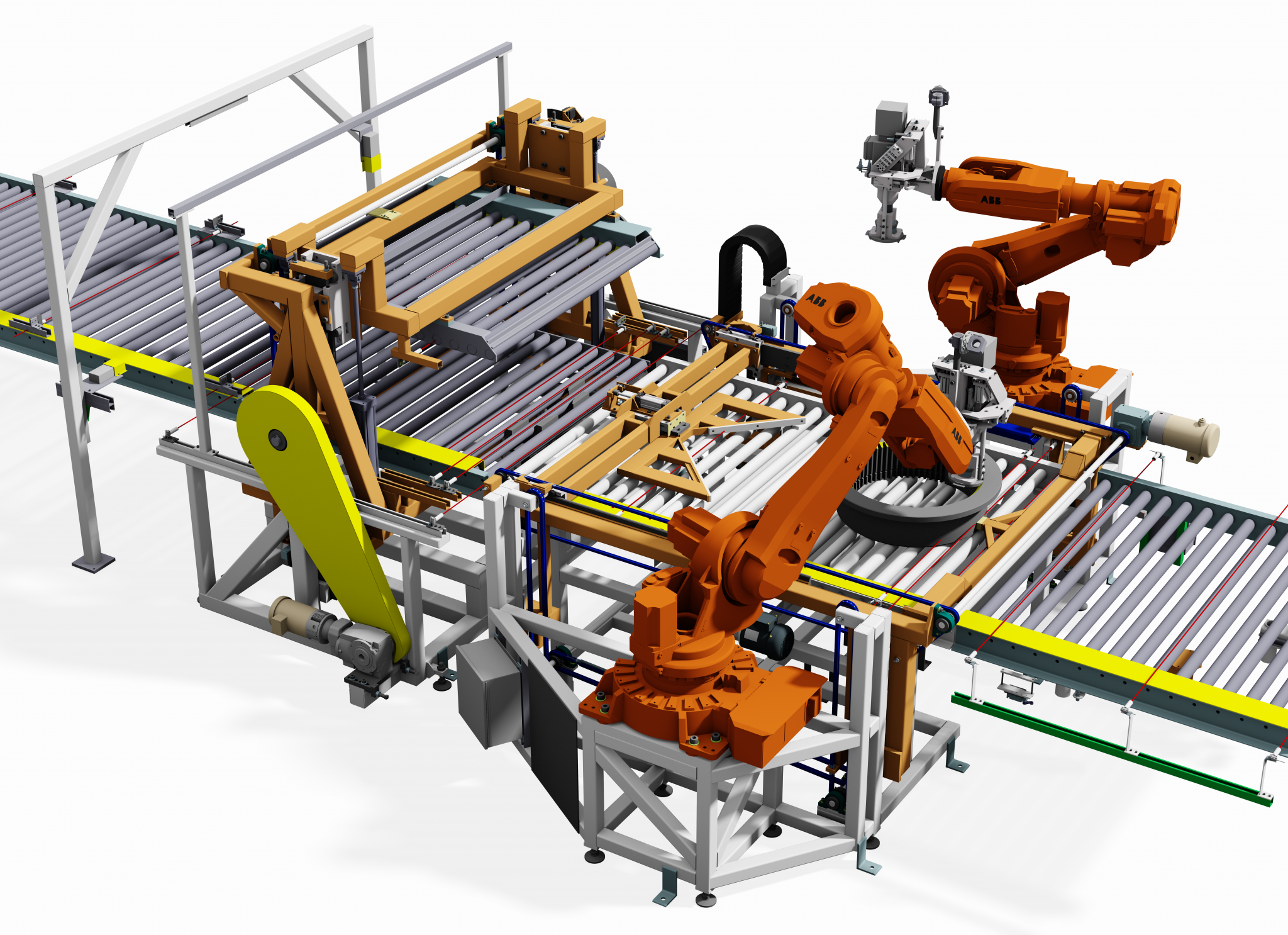

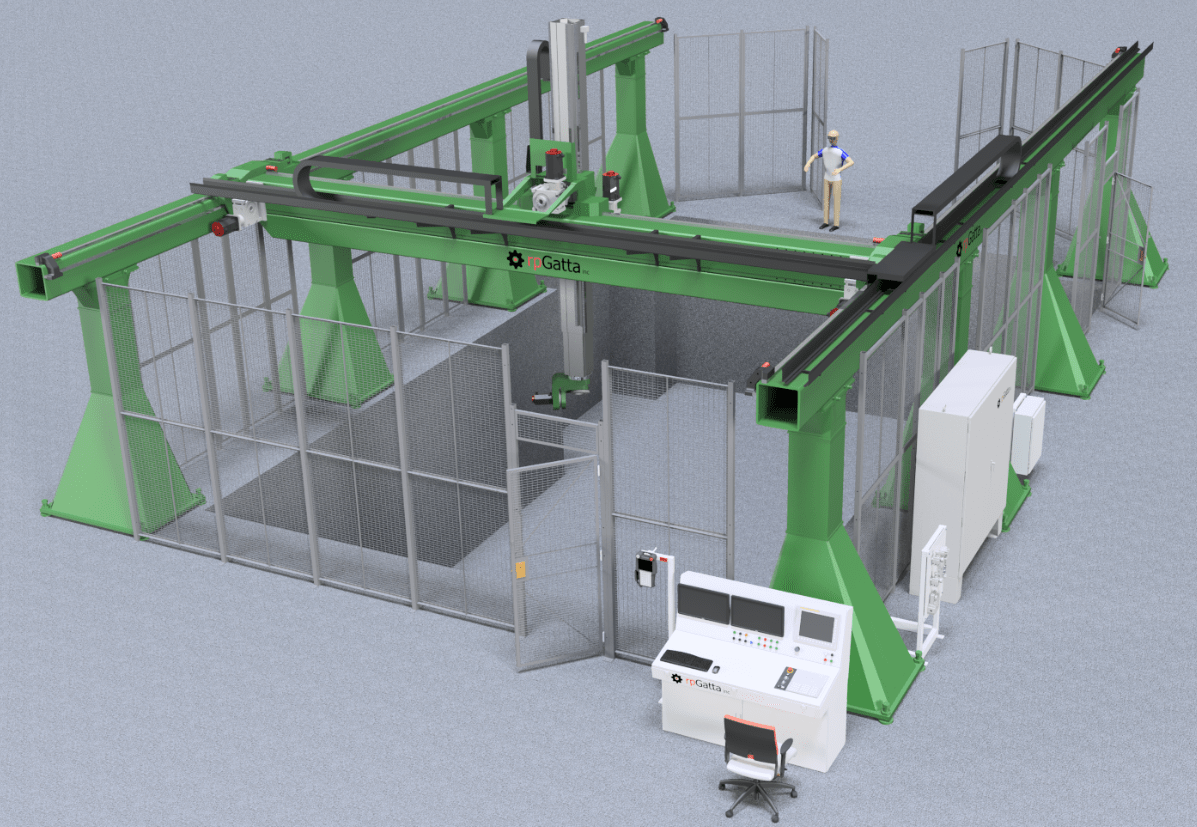

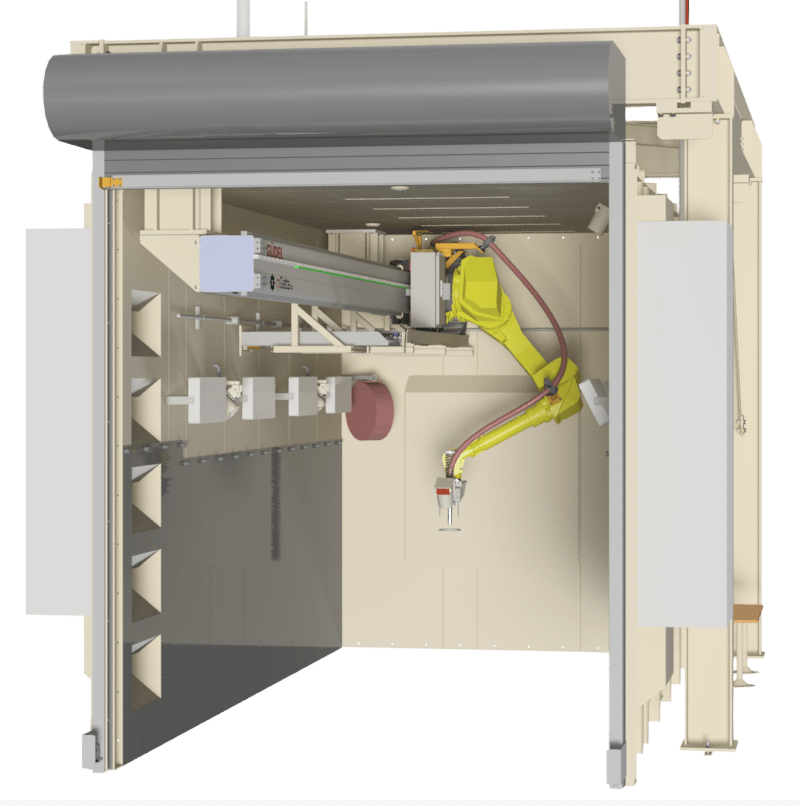

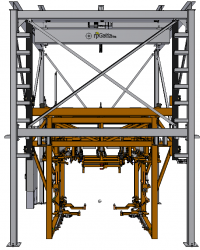

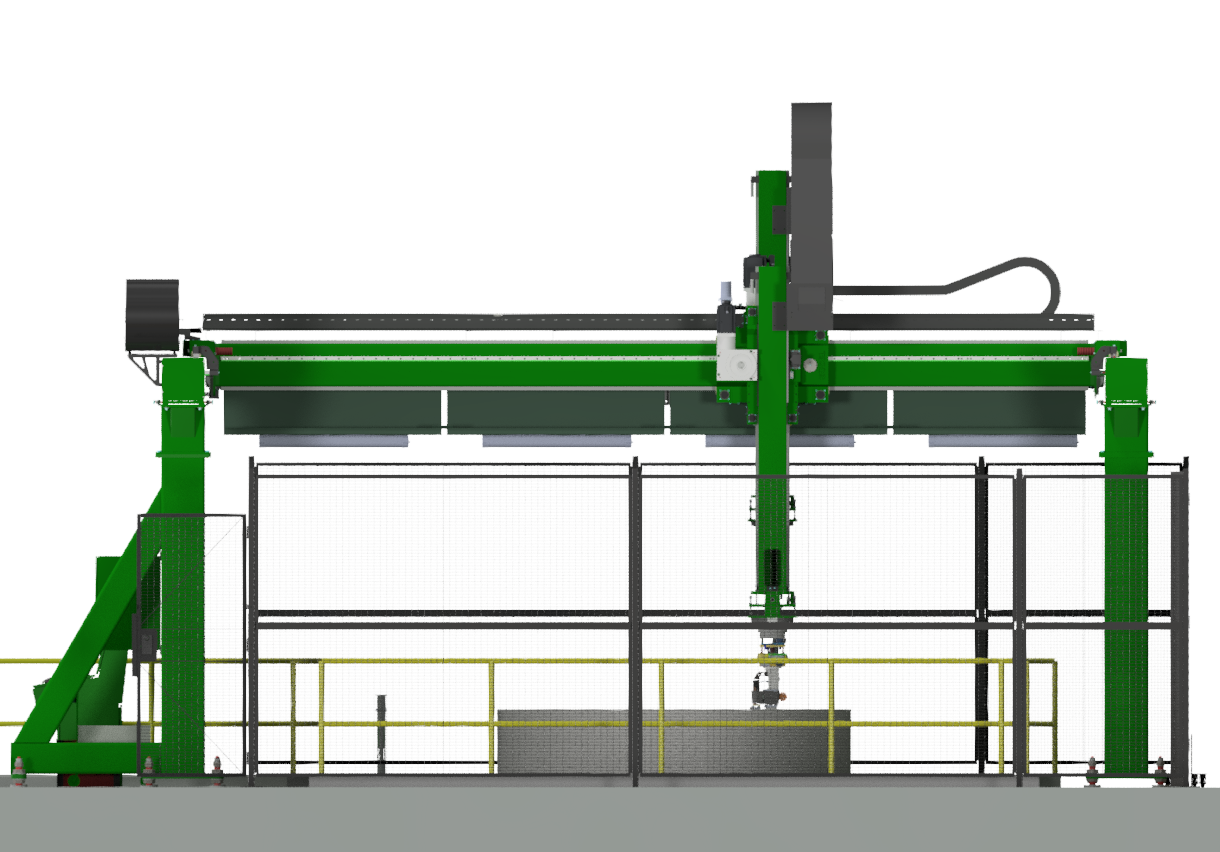

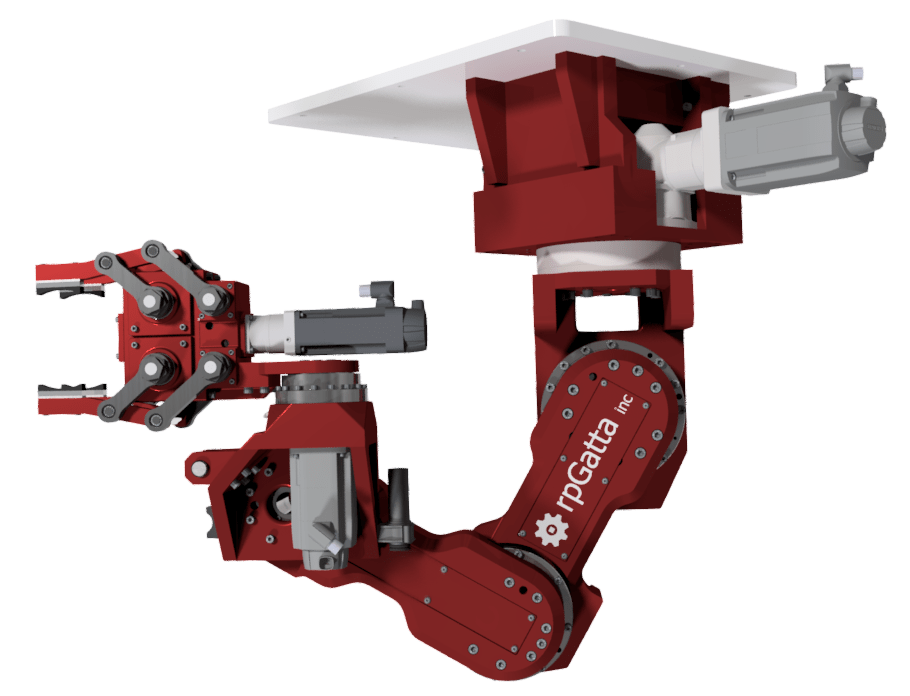

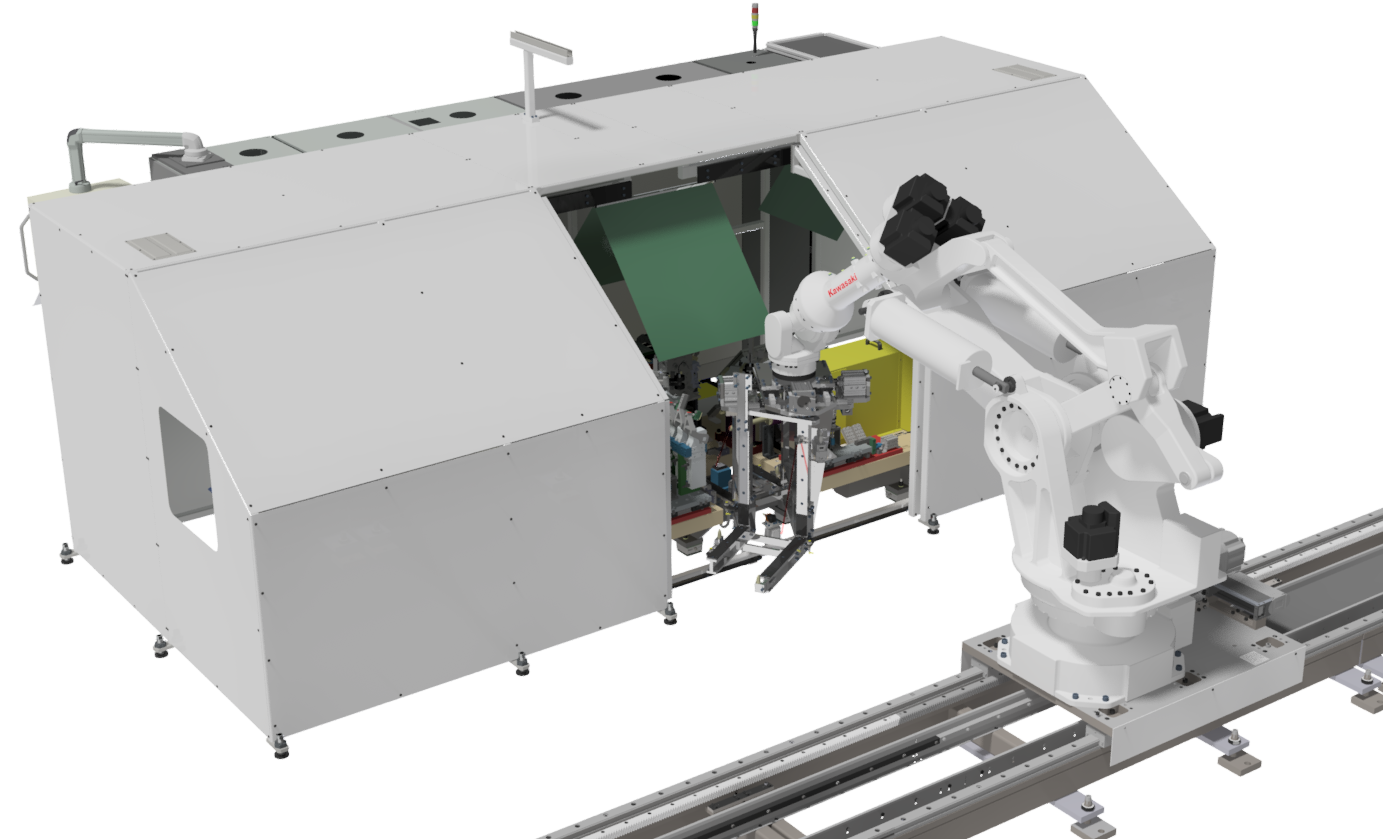

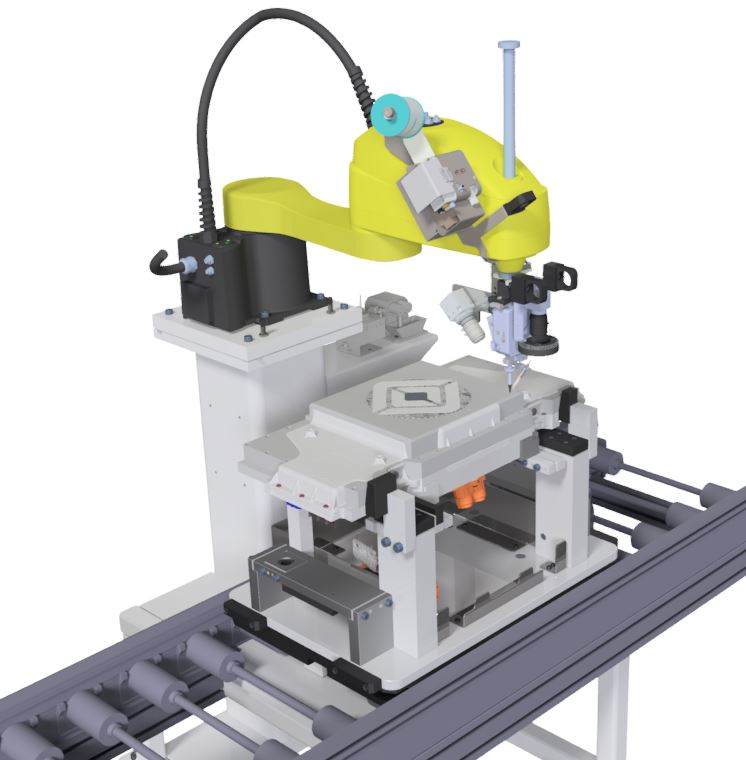

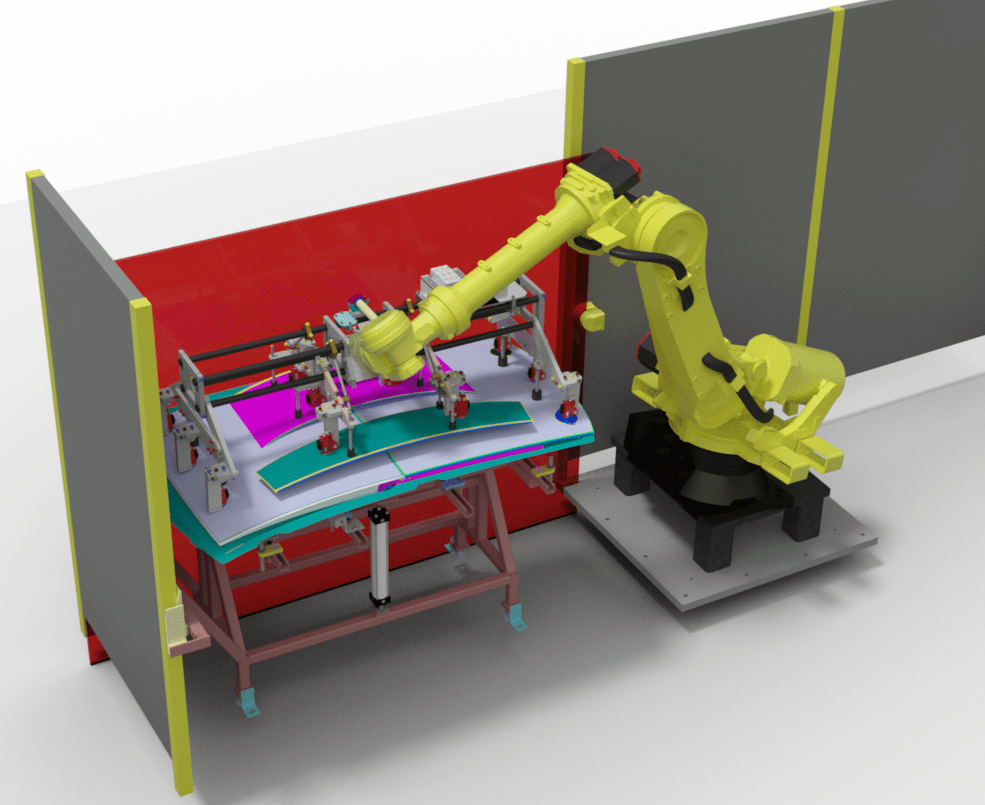

Robotic integration

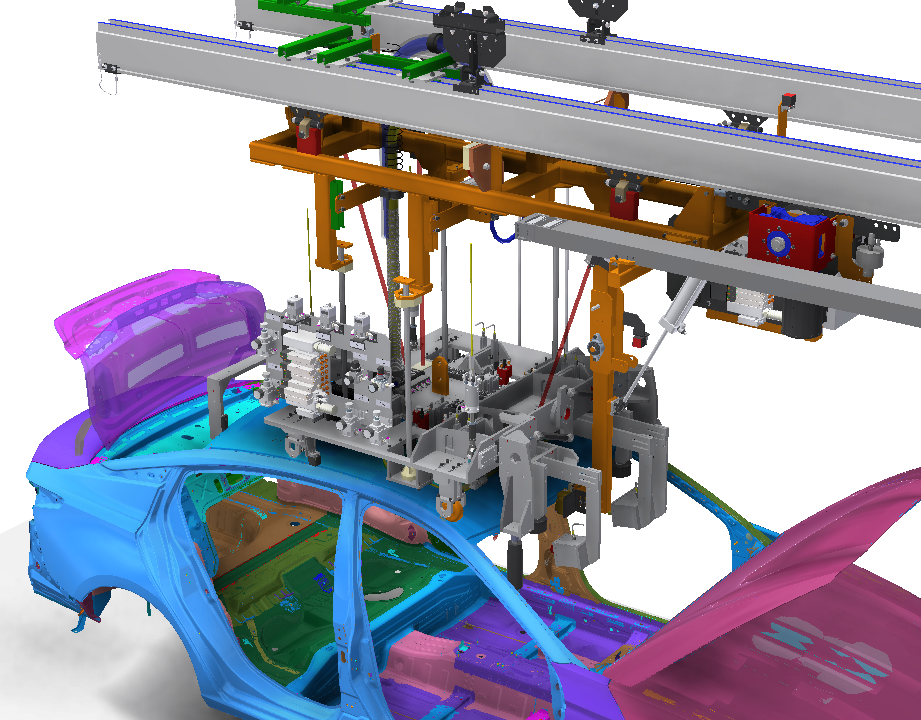

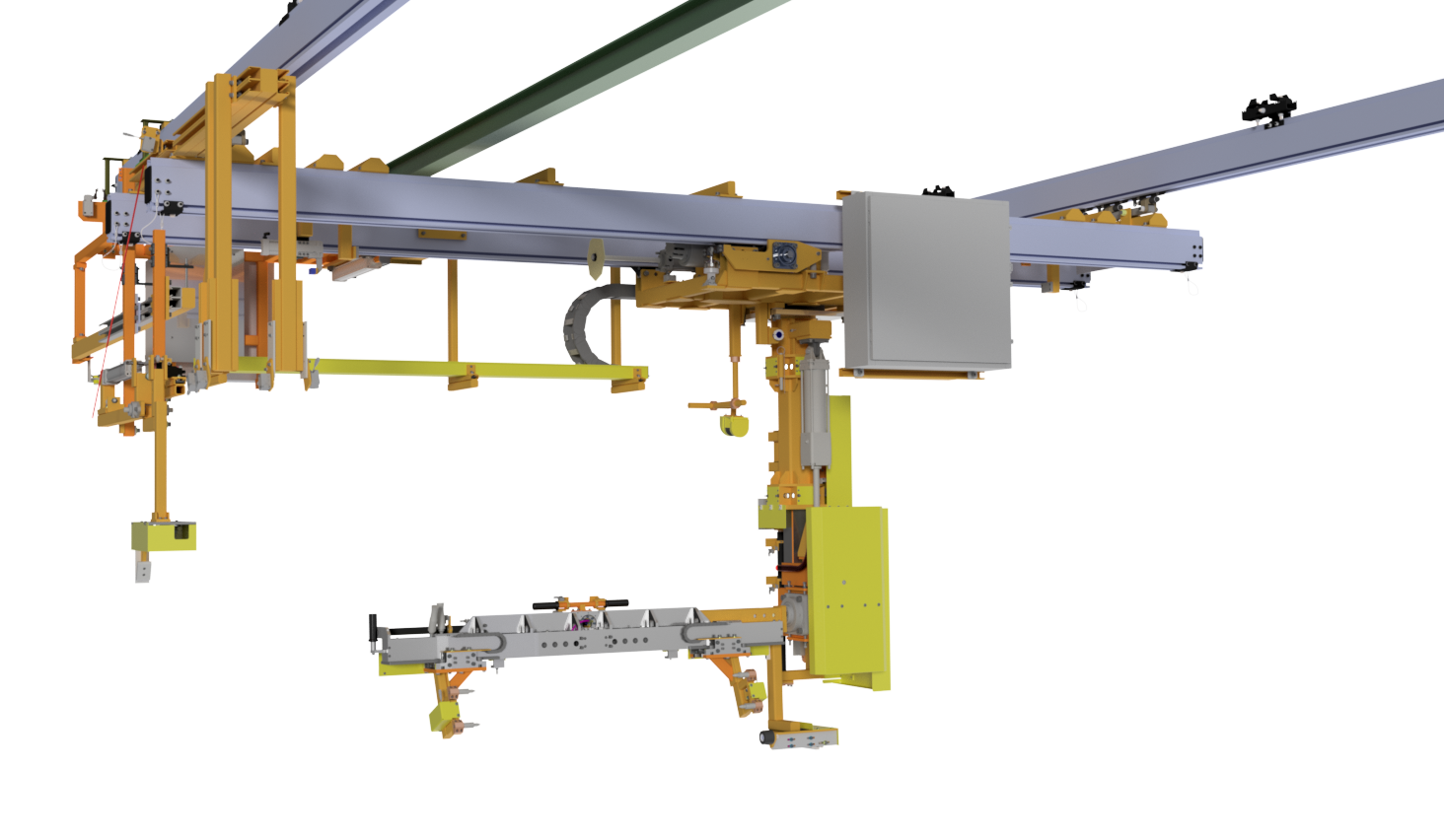

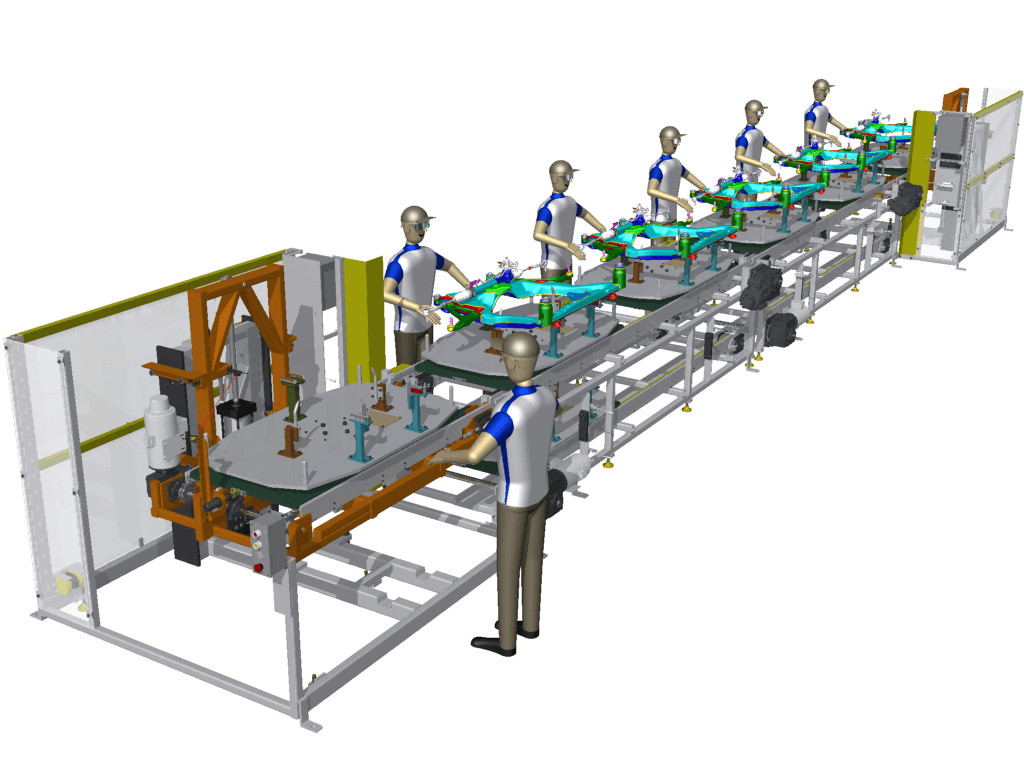

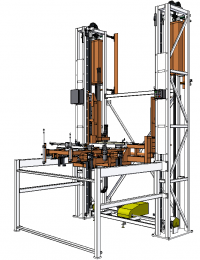

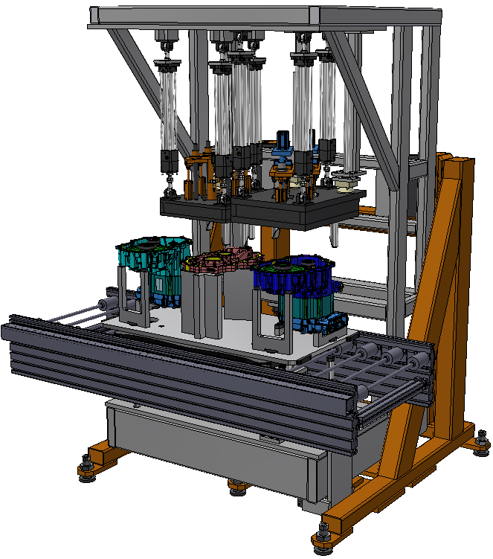

Assembly Line development and Integration

line tracking

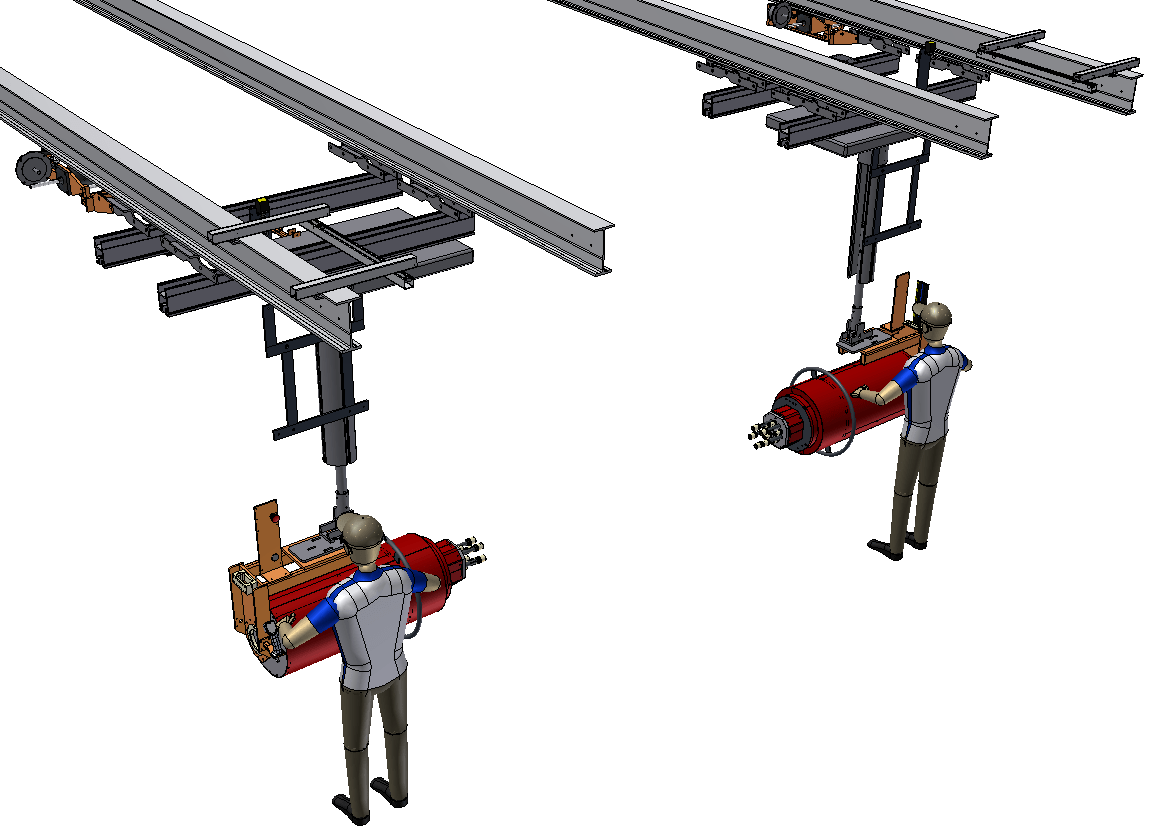

Ergonomic assists

fastening

servo pressing

material handling

Dispensing

assembly machines

Deburring

cnc Integration

headlamp aiming

de-painting

laser engraving/

Metal Marking

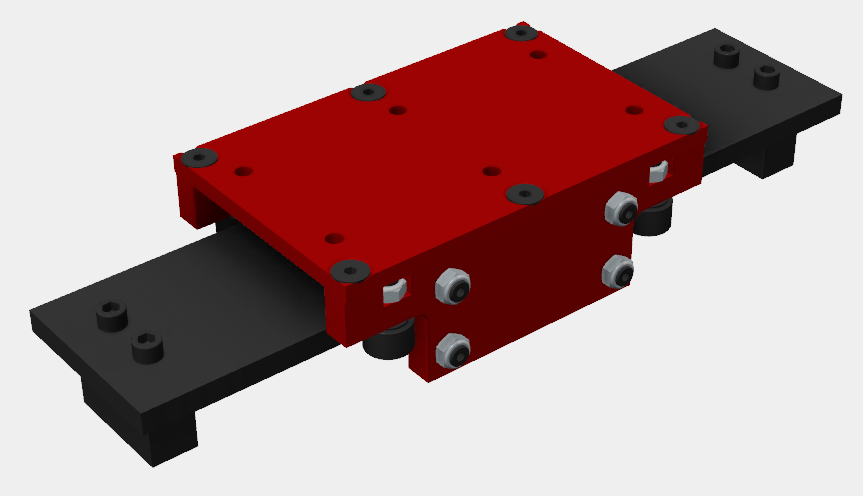

Fixturing

welding

custom robot arm design

End of Line Test Systems

conveyors

Leak Testing

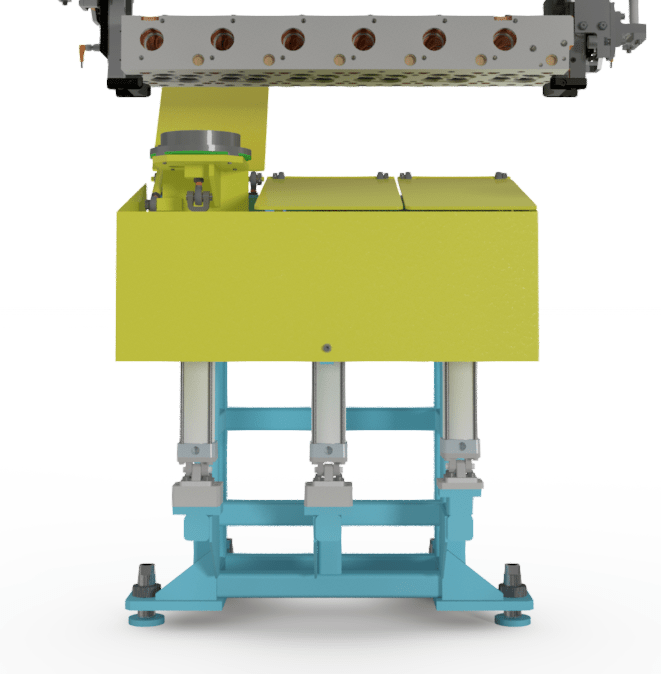

lift systems

soldering

measurement & Gauging

2D & 3D Vision Inspection

HD Slides

Experienced integrators of the following: