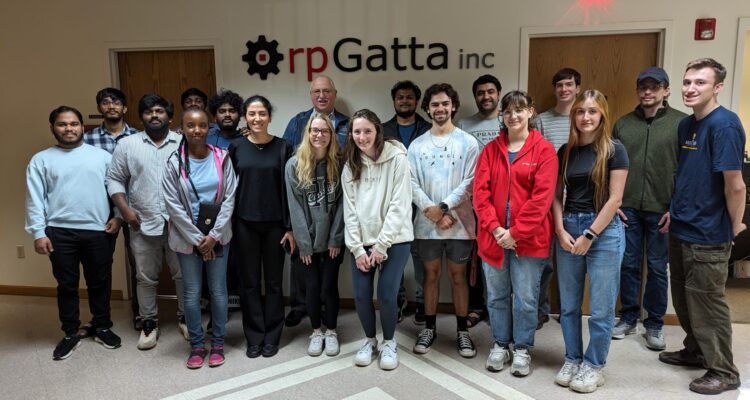

Kent State University Mechatronics

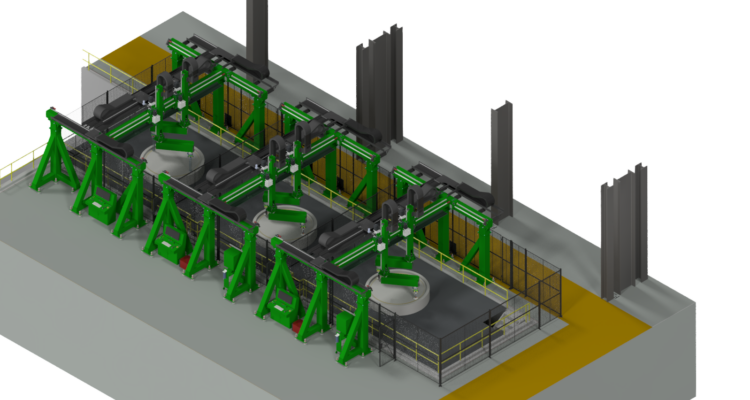

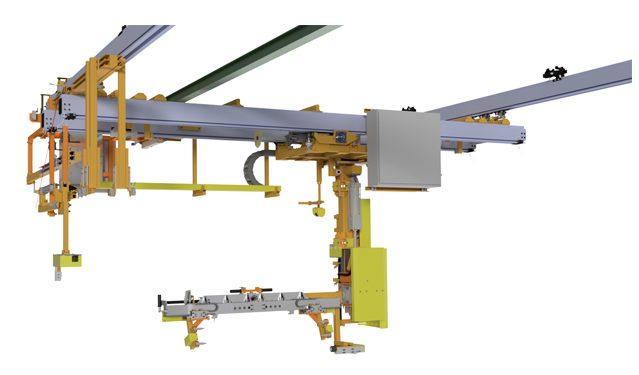

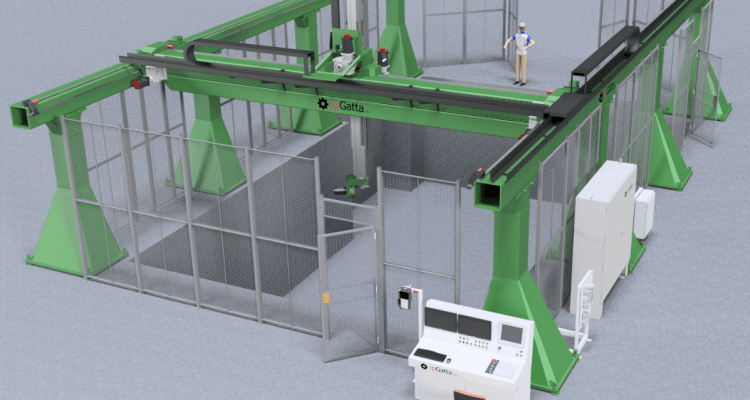

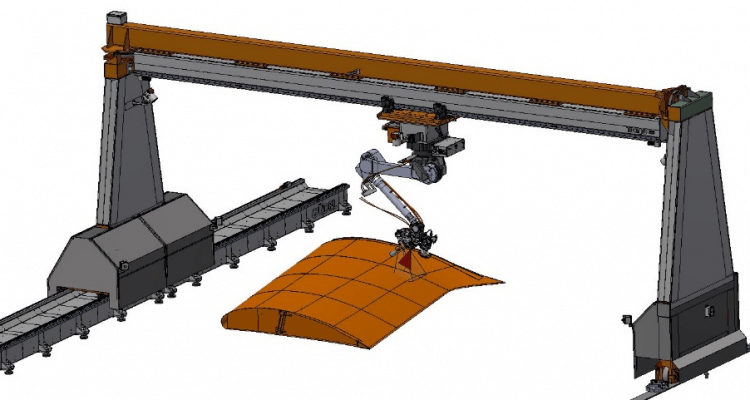

We were happy to host a tour for a group of KSU Mechatronics students studying under Professor Boyd. The students were able to see a number of rpGatta robotic cells automatically assembling electric vehicle components. It's exciting to see the…