Leak Test Automation

We currently have a U.S. Patent Pending for a new Battery Leak Test System that utilizes a flexible bladder to tightly seal around a contoured surface.

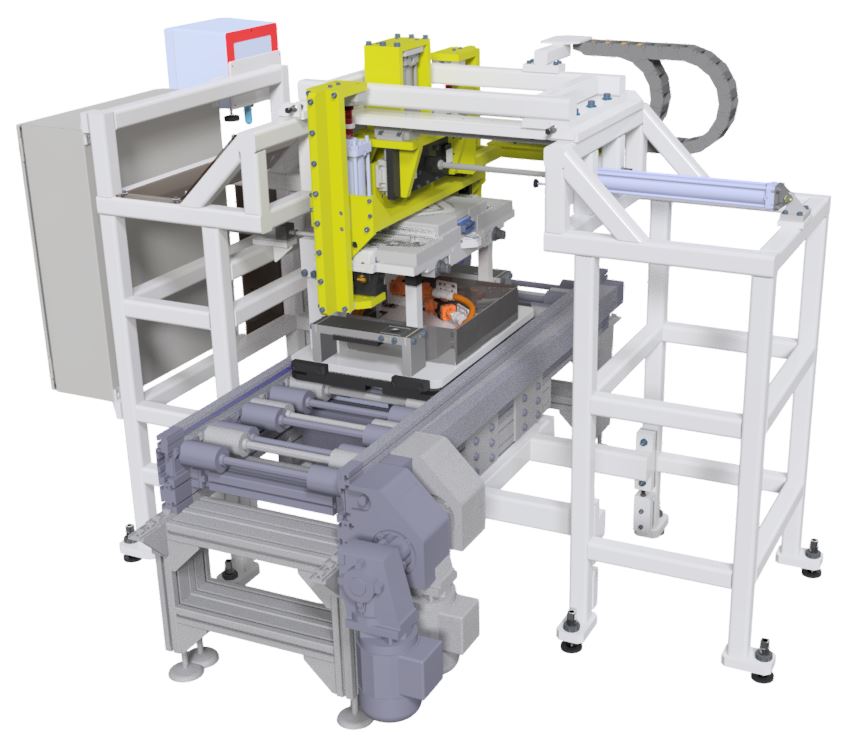

Cylinder Head Leak Test Stand

Features:

With this system a robot brings over 3 different model cylinder heads and performs a leak test around the valves to verify the seals work to spec. Depending on which model head is brought over the appropriate test fixture will actuate up and then is automatically covered when actuated back down to prevent dust accumulation.

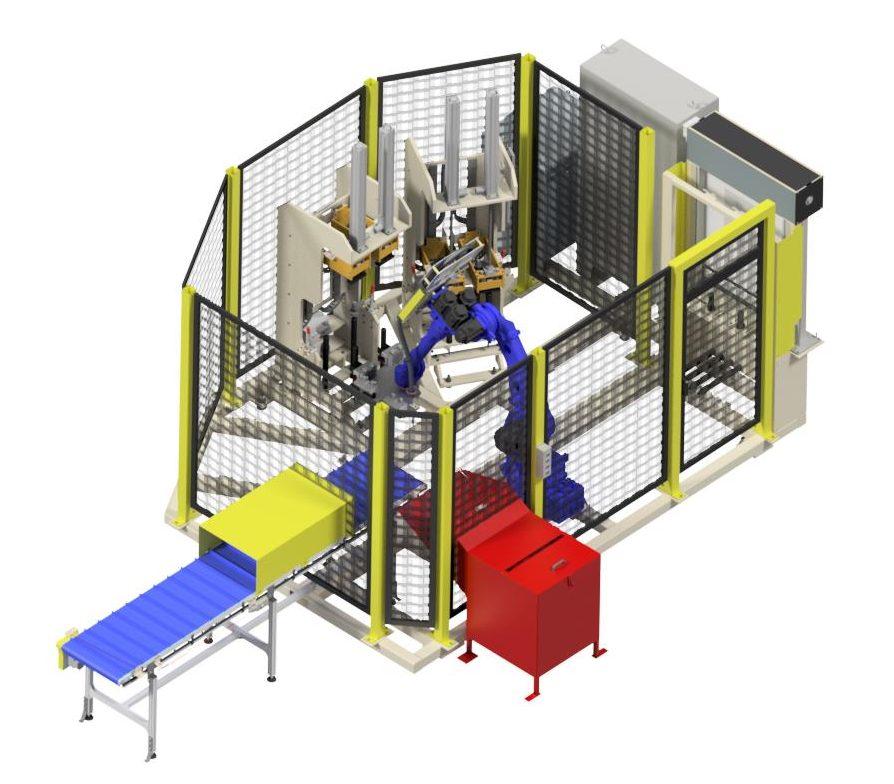

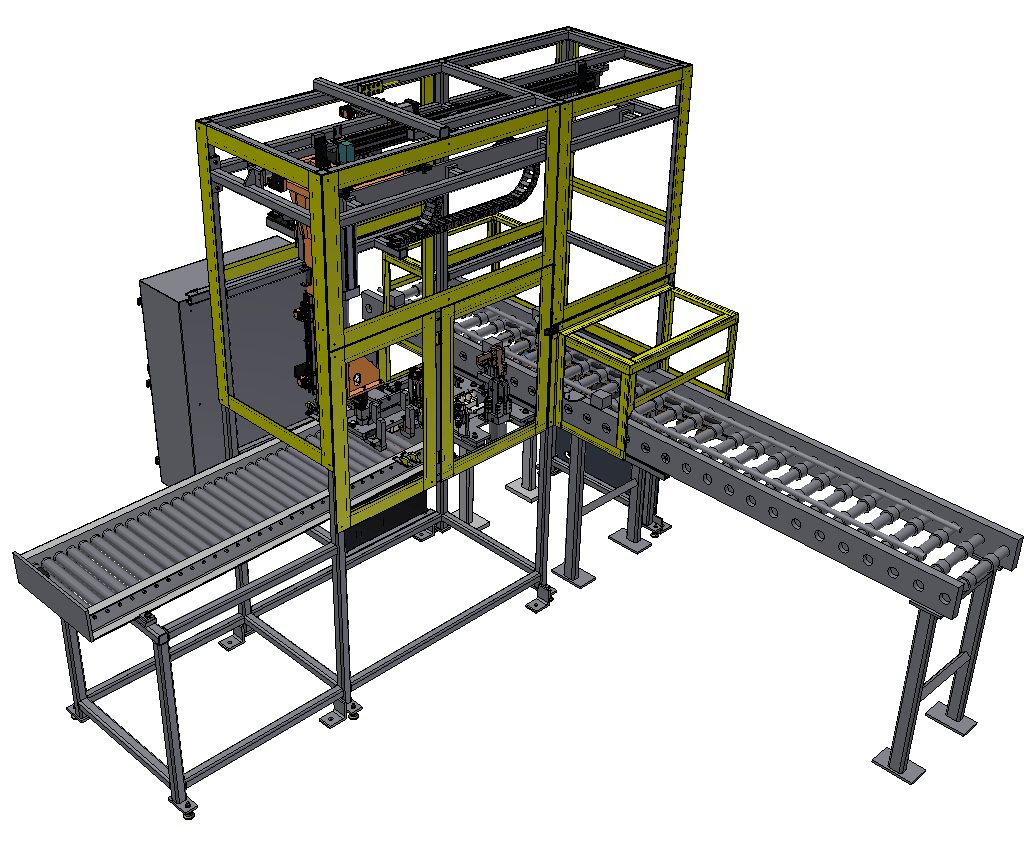

Robot RTA Leak Test Cell

Features:

- The Leak Test Machine consisted of the following main components:

- Stand Alone Machine Frame

- Operator Load Station

- Motoman MH50 II Six Axis Robot

- Custom Design Robot End Effector

- (3) Leak Test Stations

- Unload Conveyor

- Fast-Action Loading Door

- Reject Bin Cart

- Error Proofing Features

- Controls & Safety

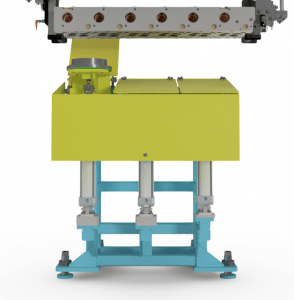

Air Cavity Leak Test

Features:

- Integrated into the conveyor line

- In-line lift and locate for the part on the pallet

- Automatic air cavity leak test equipment

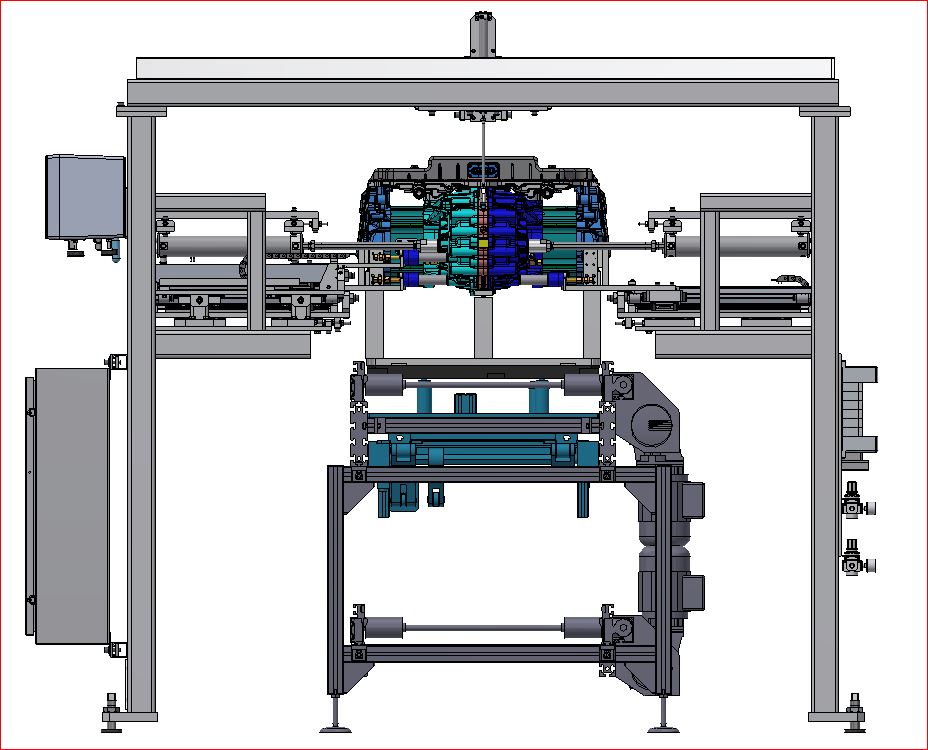

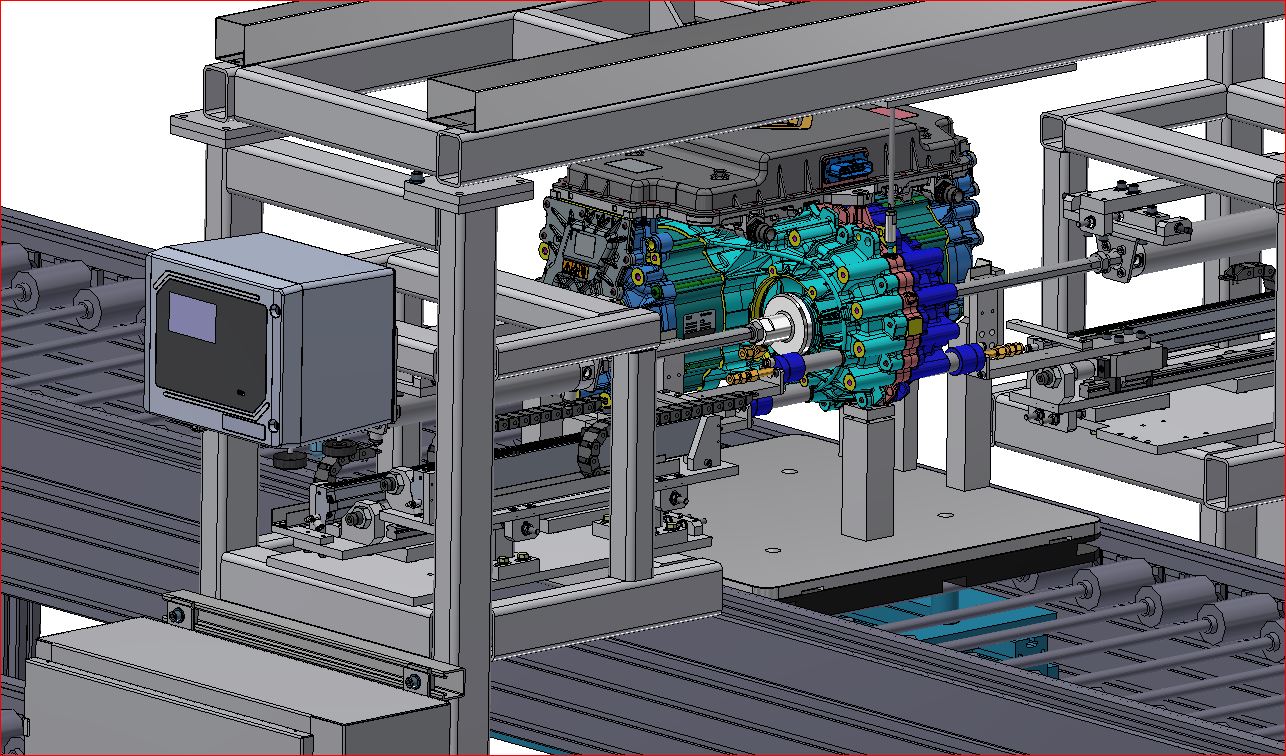

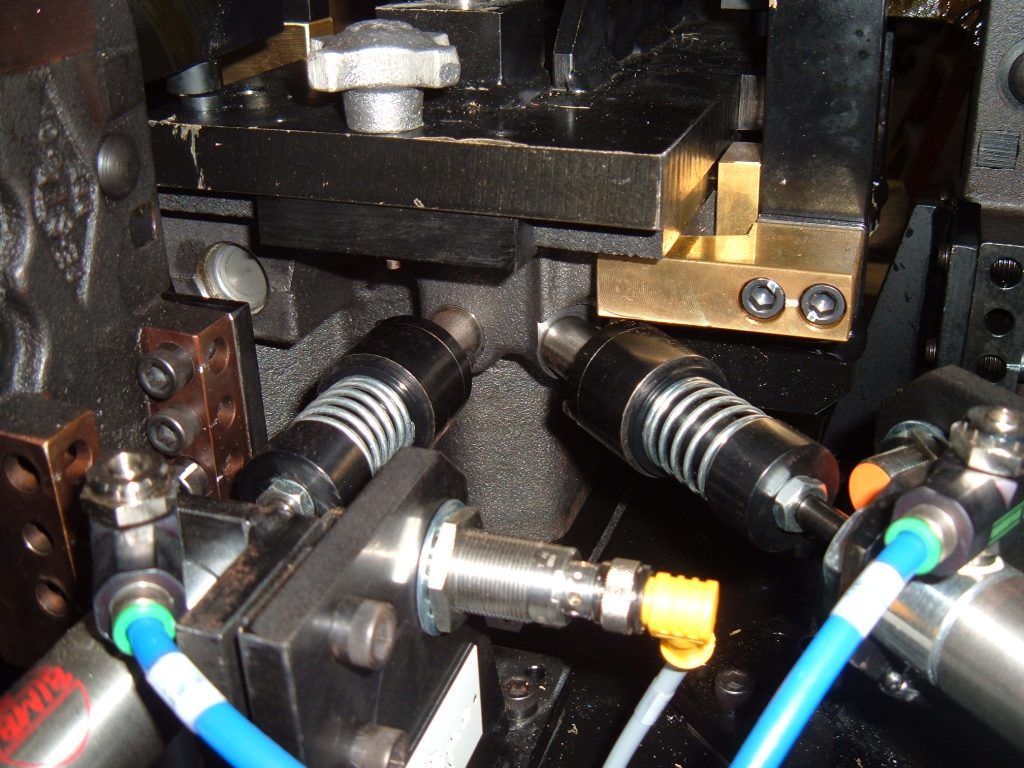

Cylinder Head Leak Test Conveyor

Features:

This system conveyed cylinder heads in on a conveyor to a fixturing station which located the cylinder head. Leak test heads pneumatically actuate in to seal the required holes in the cylinder head. Readings were taken by the CTS equipment and displayed on an HMI monitor.

Oil Leak Test Station