Marking Systems

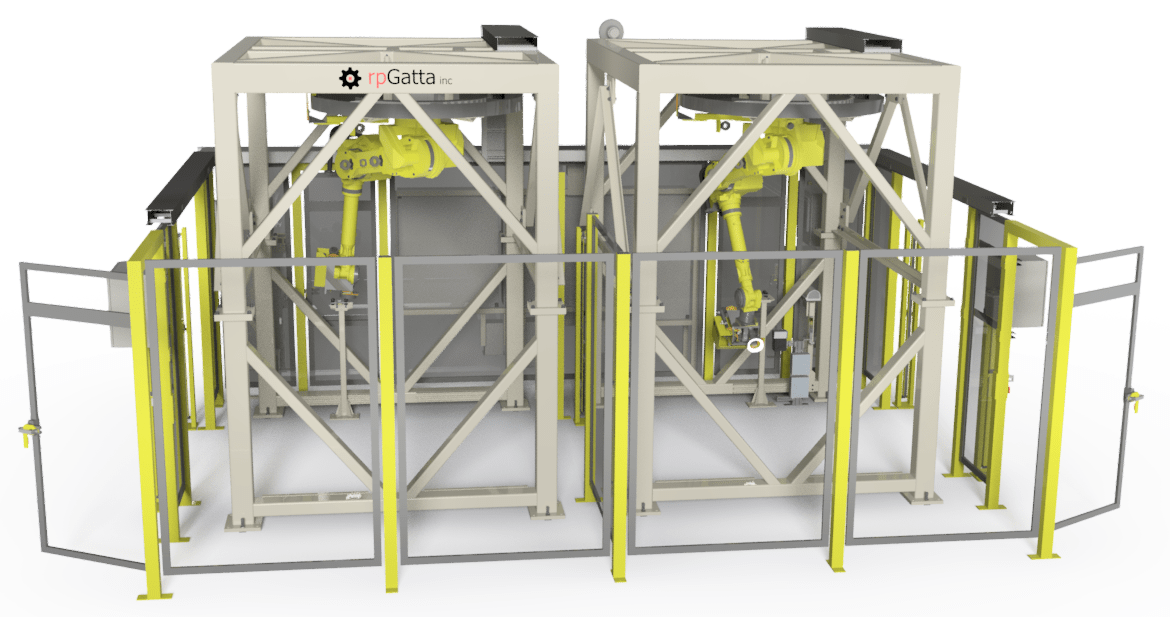

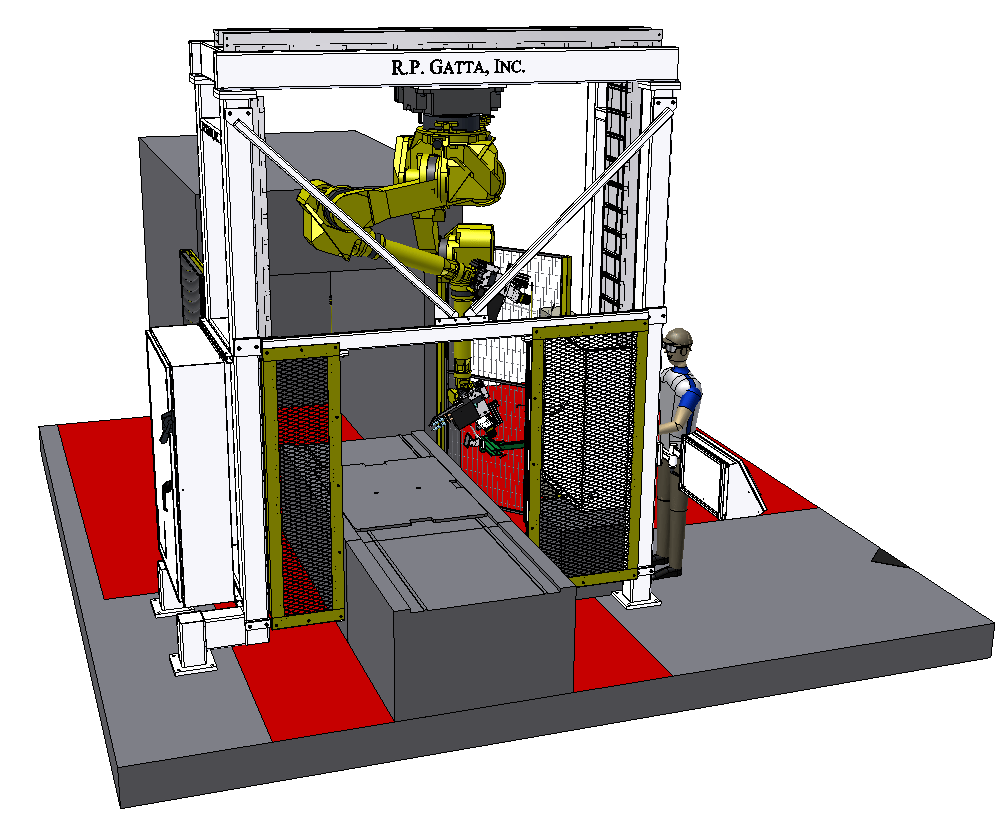

Robotic VIN Stamping Cells

Features:

- Robots capable of reaching both sides of the engine.

- The end of arm tooling on the robots use a vision system to locate the engine, inspect the marked surface for defects, mark the VIN number, then read the marked VIN number to error proof the mark and pass/fail the VIN readability.

- Systems include marking test stands inside the safety fence with accessibility from the outside using a request to enter button.

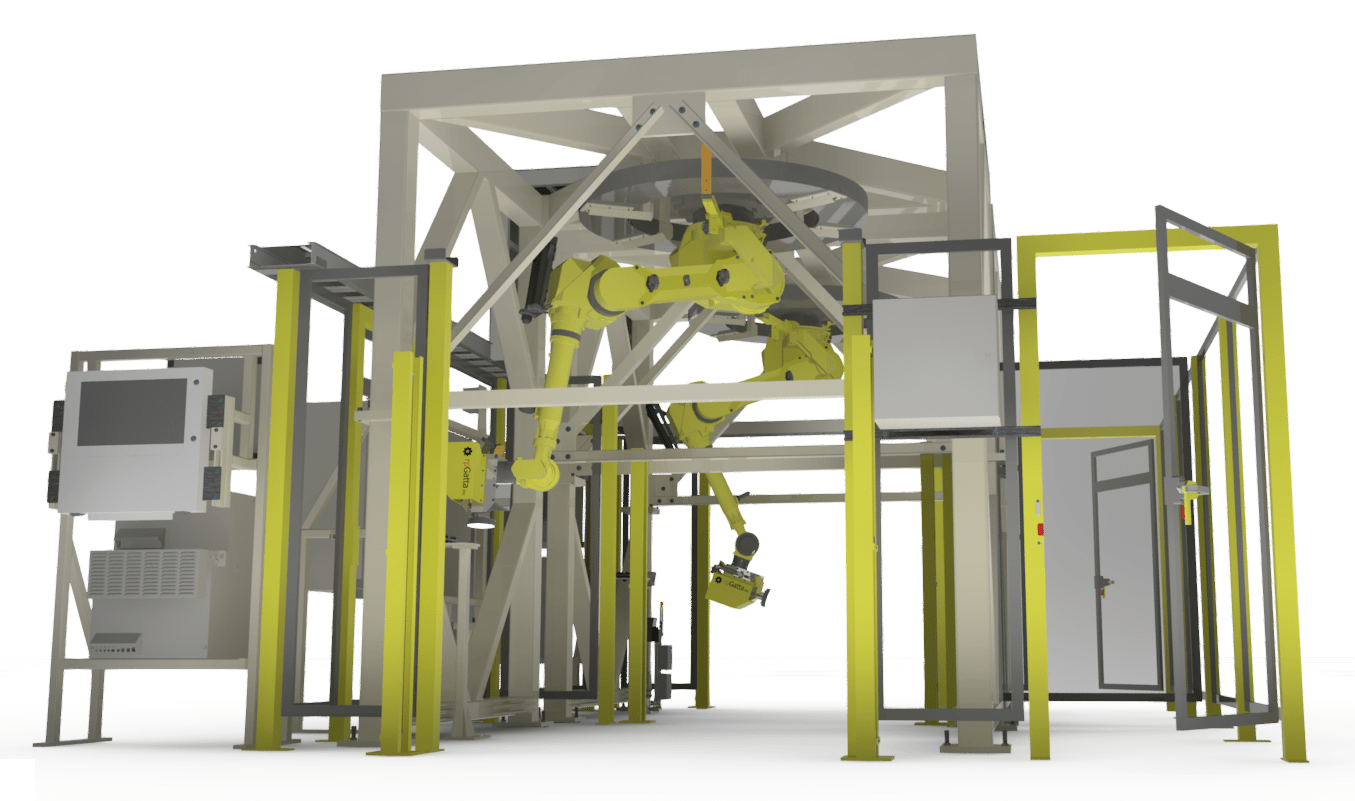

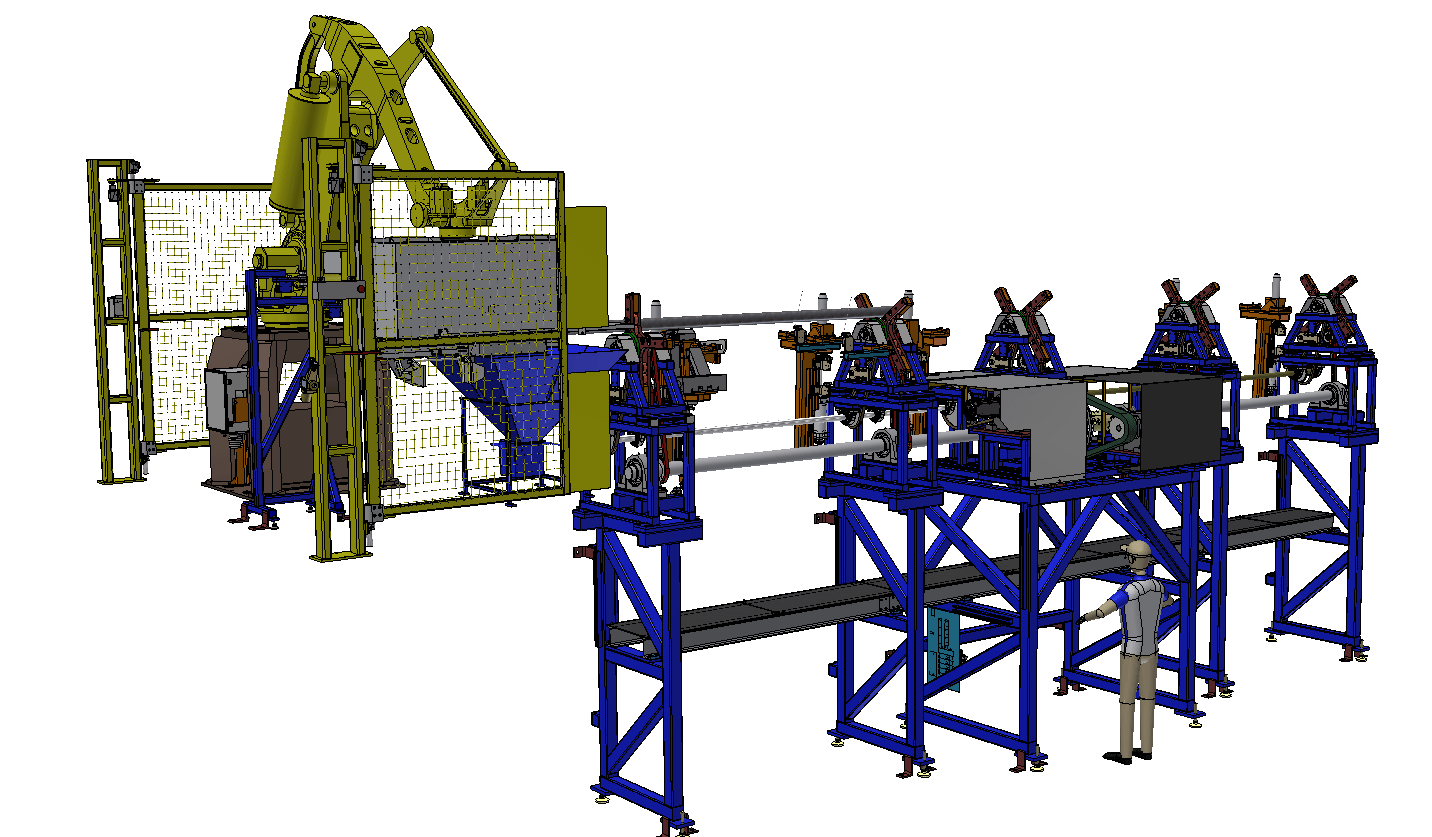

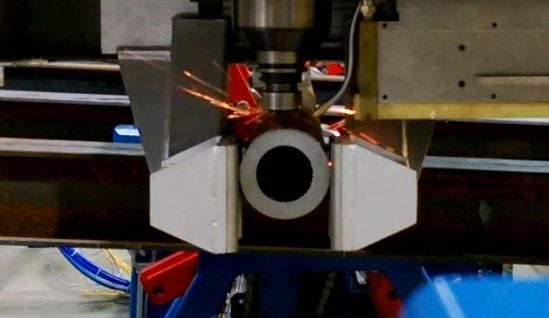

Robotic Tube Milling and Marking System

Consists of:

- High temperature marking unit tube flat marking surface machining unit

- Tube broken end measurement system

- Robotic positioning system

- Tube lift and rotate system

- 2-D bar code inspection unit

- Tube straightness inspection system

- Water cooling system

- Safety protection

- Controls system

Features:

- Automatic tool changer controlled by 3 drawbar sensors and double acting pneumatic actuator

- Pneumatically actuated clamp to hold tube securely during machining and marking operations

- Utilizing the Robot's servo motor encoders for displacement feedback, a 3D model of the data is created

- Custom software to analyze the 3D model to determine how much to rotate the tube to the optimized position for the surface to be machined and marked

- Tubes are lifted by pneumatically actuated pivot arms mechanically synchronized with a common pivot shaft

Error Proof Scriber Systems

U.S. Patent No. 7,055,426 B1

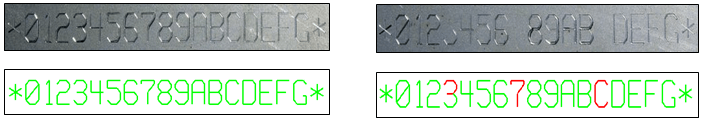

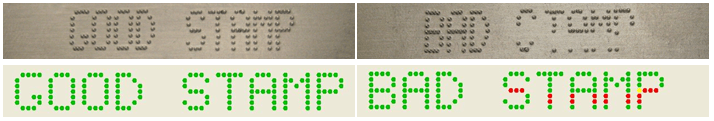

Sample Scribes (Passing and Failing):

Features:

- Imprints a surface accurately and permanently to form a scribe of alphanumeric characters

- Error Proofing:

- Electronically monitors the pin engagement to the work piece during the entire scribe

- Displays a graphic representation of the scribe results on the monitors, where any portions of the scribe that failed to engage the work piece will turn red

- Monitors system torque to anticipate tool wear or breakage

- System Components:

- Scriber head

- Standalone computer Ice Station containing a PC, monitor, keyboard, mouse, and standard industrial controls components

- Windows Operating System

- Error Proof Scriber Software

- User friendly graphical interface

- Graphical representation of error proof scribe results

- Serial and Ethernet communications

- Onboard history log

- Data results can be sent to supervisory system for retention

- Error proof scriber system can be customized to suit customer needs

- Typical applications include:

- Product and part identification

- Vehicle frame identification number

- Body hidden VIN

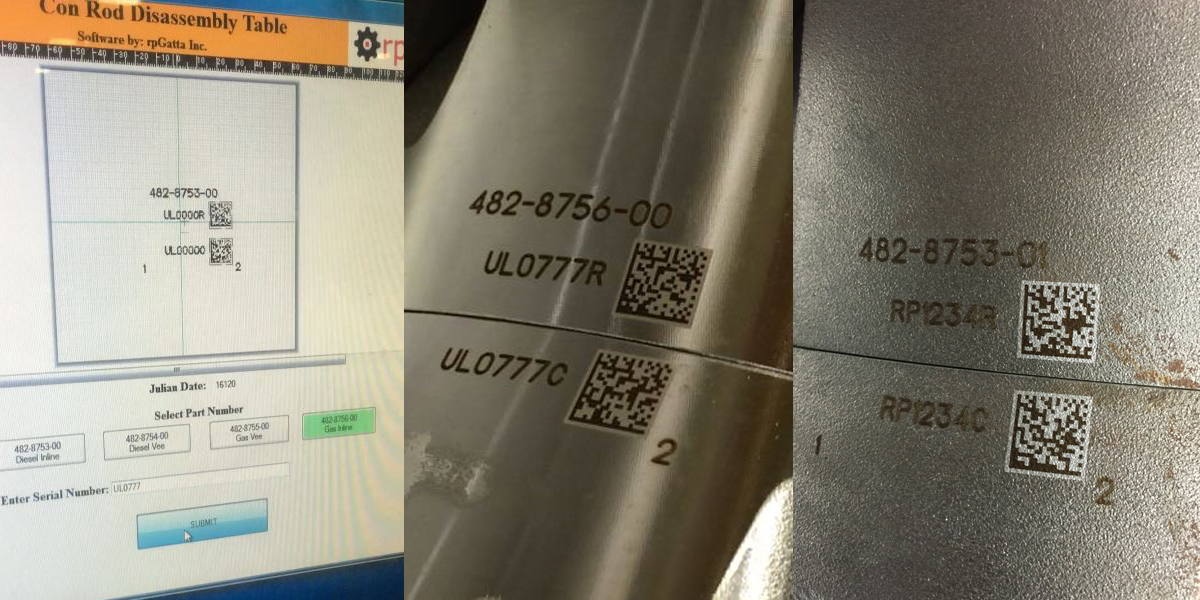

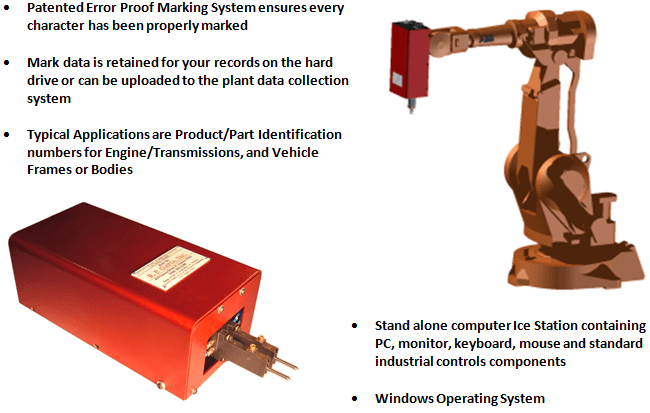

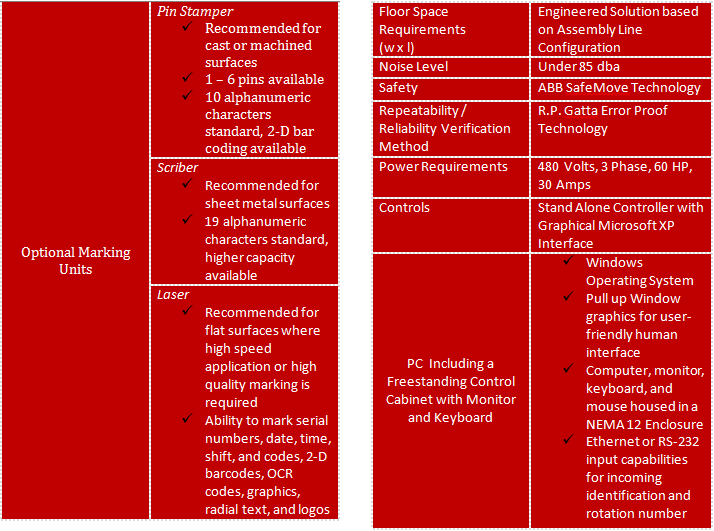

Error Proof Pin Dot Peen Marking Systems

U.S. Patent No. 6,719,468

Features:

- Marking System Imprints a Surface Accurately and Permanently to Form a Dot Matrix of Alphanumeric Characters

- Error Proof Marking System:

- Detects the engagement of every marked dot by utilizing a high-speed electric continuity circuit Monitors the speed of the pins to ensure the proper impact on the marking surface for each and every dot

- Records the engagement of every dot for data collection as the dots are being marked

- Displays the rotation number, predetermined marking, time, and date graphically

- Stores and prints results (if desired)

- Each Error Proof Marking System Includes a Freestanding Control Cabinet with Monitor and Keyboard:

- Windows Operating System

- Pull up Window graphics for user-friendly human interface

- Computer, monitor, keyboard, and mouse housed in a NEMA 12 Enclosure

- Ethernet or RS-232 input capabilities for incoming identification and rotation number

- Patented Error Proof Marking System Ensures Reliable Results

- Typical Applications Include:

- Product and Part Identification

- Engine/Transmission Identification Number

- Frame Identification Number

- Body Hidden VIN

- Error Proof Marking System can be Customized to Suit Customer Needs

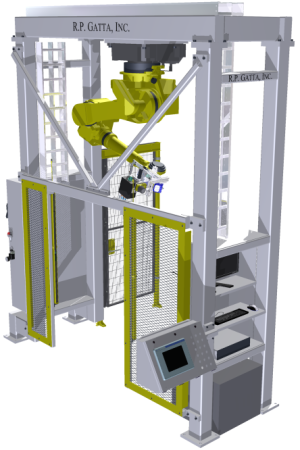

4000i Series Fully Integrated Marking System

Features:

- The 4000i integrates rpGatta’s Error Proof Marking System on an 6-Axis Robot Platform providing a flexible and reliable automated marking system.

- Error proofing vision

Sample Stamp Marks (Passing and Failing):

Series 4000i Specifications:

Laser Engraving Integration