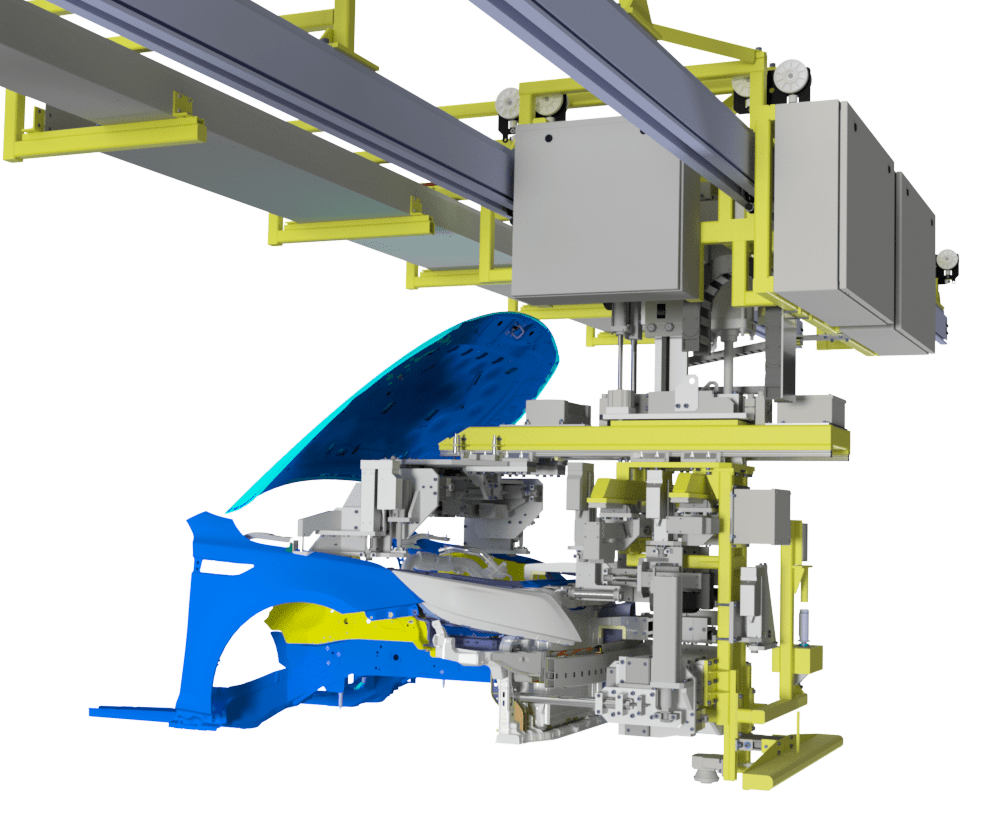

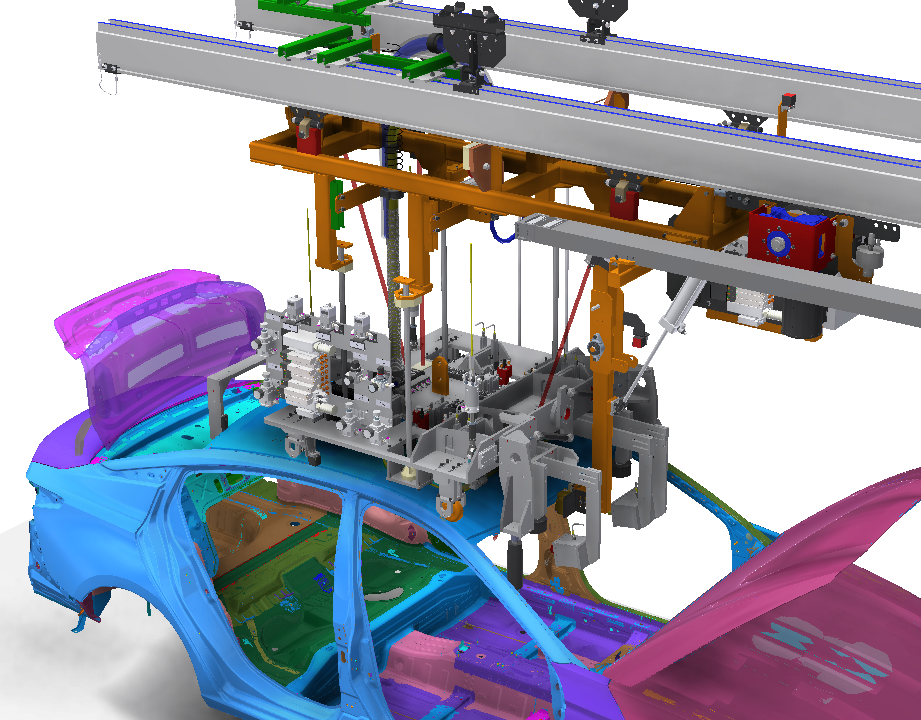

Smart PLC Controlled Assists

Dash/Instrument Panel/

CPM Decking Assists

Features:

- Servo-driven runway and bridge rail motions

- Robo cylinders to electrically control the height, tilt, and insert positions and movements of the assist on the fly

- Mechanical compliance built into the assist arm to allow for compliance in the roll and yaw axes

- Lightweight aluminum arm frame to decrease weight while still maximizing body side clearance

- Pneumatically actuated pin slides to adjust for multiple models

- Over travel stop mechanism to increase safety and efficiency

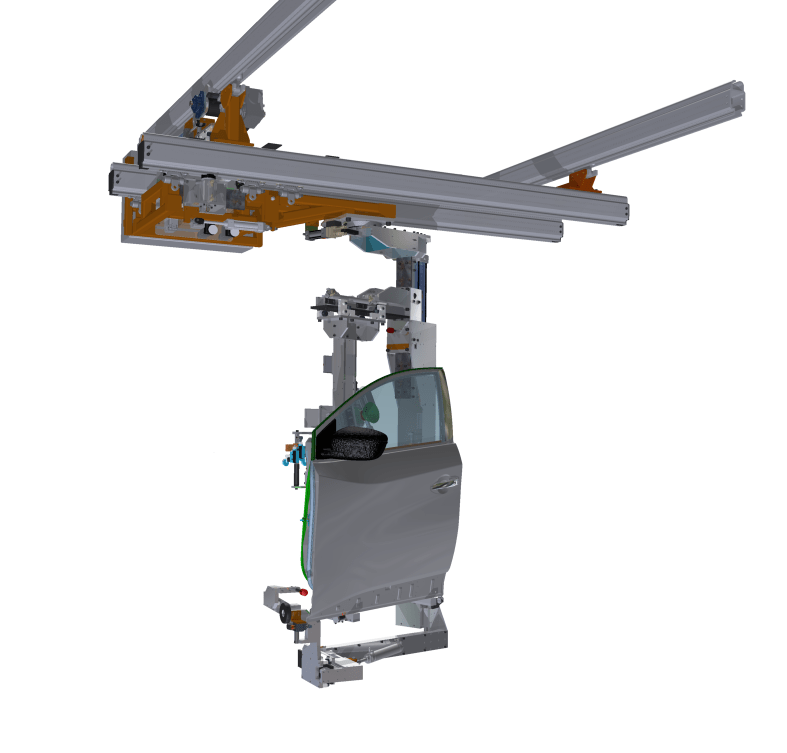

Doors On/Doors Off Systems

Features:

- Easily remove the doors from the door drop lifter and transfer to the vehicle body for installation

- Overhead rails mounted on dual runway and dual bridge rail system for movement in 2-axes

- Assist’s weight and size is minimized to maximize the ergonomic benefits of the assists for the technicians

- Pneumatically actuated brake to allow operator to lock assist into position

- Door assist handles with electric operated thumb switches to control the following operations of the assist: “Grip Door,” “Release Door,” “Common,” “Raise Door,” “Lower Door” and “Brake”

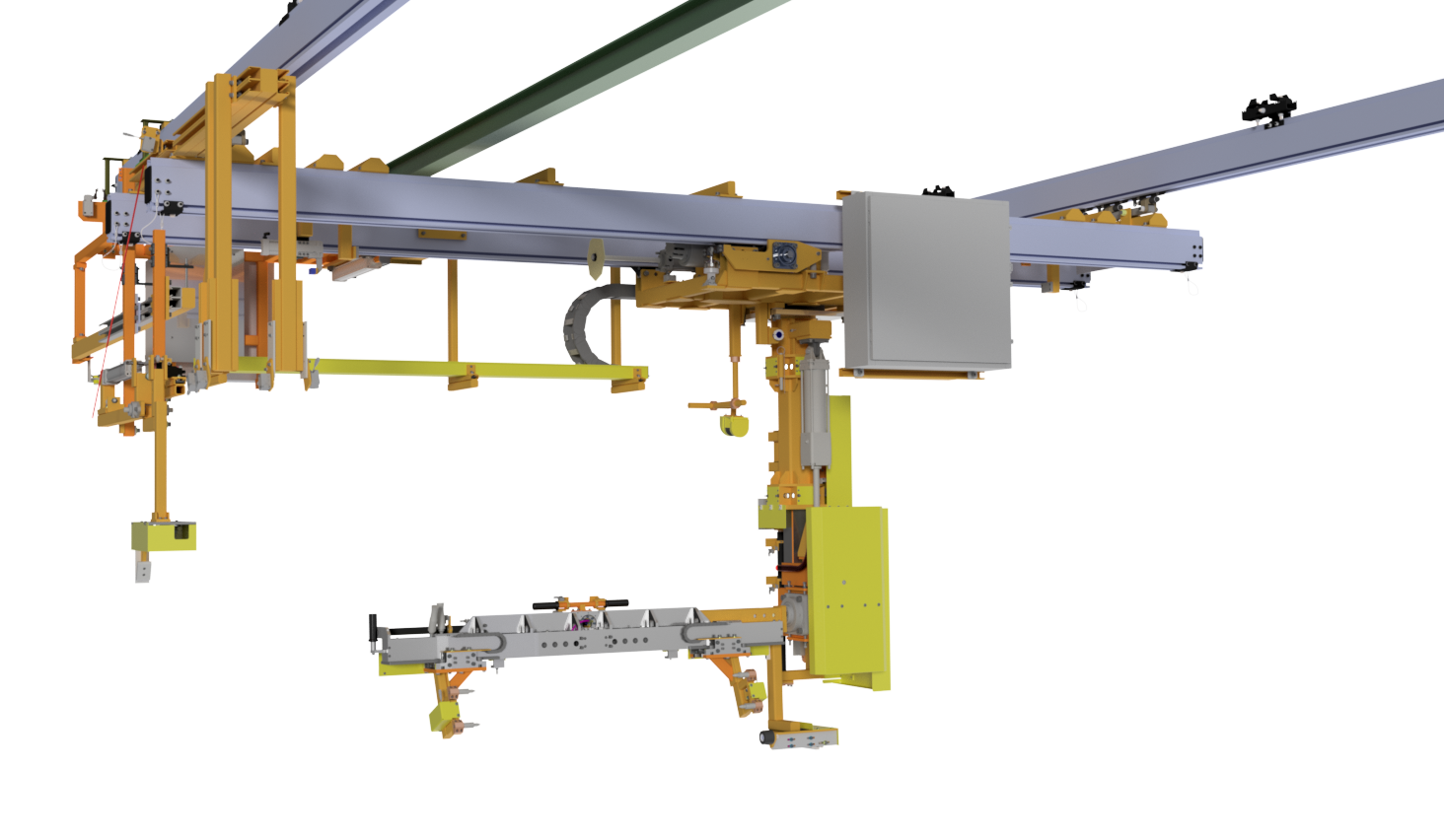

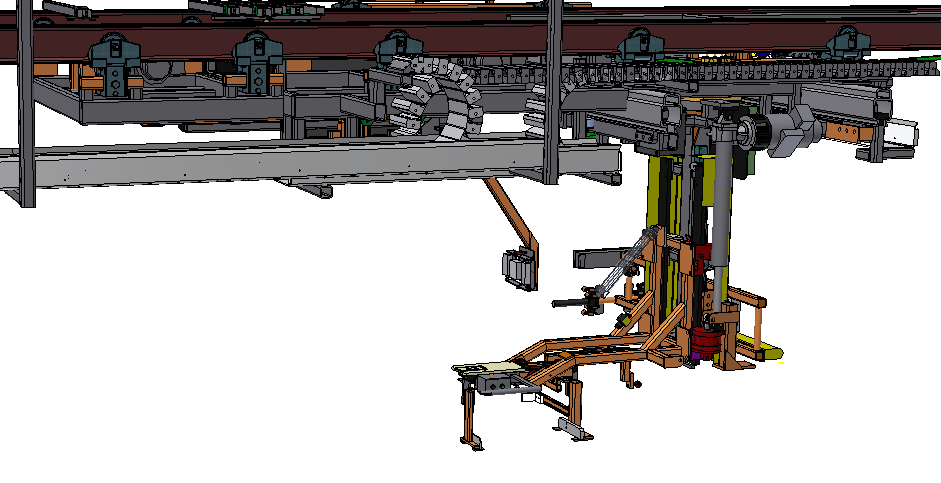

Fuel Tank Install Assists

Features:

- Fuel tank end effector will manually pivot out from under the body carrier area when not in use

- Air Over Oil Caliper Brake to control pivot motion

- Practical Intelligent Assist Device (PIAD), U.S. Patent #7461753

- Spring-loaded counter balance to support weight of fuel tank

- Electric motor, clutch, and gearbox drive with friction drive wheel to return the decking fixture home

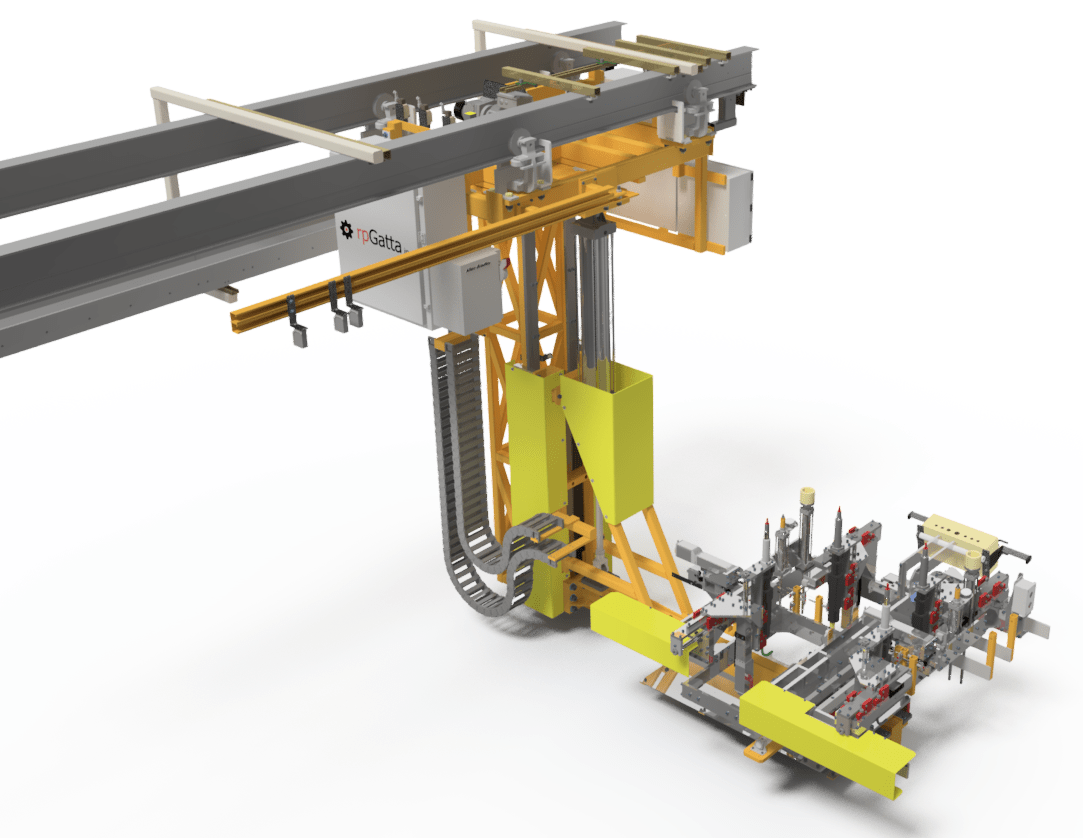

Front End Module Assists

Features:

- Practical Intelligent Assist Device (PIAD), U.S. Patent #7461753

- The Front End Module PIAD mounts overhead on ergonomic runway rail

- Dual Runway System and Dual Bridge System

- Servo Motor Drives coupled with Planetary Gear Boxes located on both the Bridge and Runway

- Dual Servo Motor Drive along the Runway and a Single Servo Motor Drive along the Bridge

- No proprietary “black box” controls

- Utilizes standard controls that meet your plant specifications, thus your maintenance department will be very familiar with these control components

- Enhanced positioning and travel capabilities

- X, Y, variable speed load cell joystick control will allow team member to quickly and intuitively drive the PIAD

- Using proven technology, the PIAD can be programmed to automatically move from point A to point B, return home, and can adjust from coarse to fine movement

- The PIAD can also be programmed with virtual limits to prevent mutilation

- PIAD’s are line tracking capable

- Pneumatically actuated centering device that pulls the Upper Locating Details together and centers the FEM between the body datums

Sunroof Gap and Flush

Features:

- The Sunroof Flush Assist automatically tracks and lowers the end effector onto vehicle

- The operator only needs to press cycle complete button

- Components:

- Dual Overhead Runway Rail

- Carriage with Tractor Drive

- Line Tracking Arm

- End Effector

- Glass Flushness Measurement

- Controls & Safety

Benefits:

- Labor Reduction: One assist to handle all models

- Labor Reduction: The assist will automatically track with the vehicle and return home automatically

- Quality Improvement: Fore/Aft programmable pressure to set the sunroof seals to minimize leaking

- Quality Improvement: Assist isn’t towed by cables which affects flushing – The assist tracks and automatically datums off vehicle

- Quality Improvement: More repeatable flushing from unit to unit

- Quality Improvement: (4) IAI actuators allow the sunroof position to be dialed in from the HMI station ±.1mm

- Uptime Improvement: Optional IAI actuators can be set on the fly from the HMI without taking the assist down to make adjustments

- Maintainability Improvement: PLC Controlled and advanced HMI features for better up time

HEV Battery Assists

Features:

- Overhead rail system with carriage to track along with the vehicle

- Assist device mounted off of a vertical torque tube manipulates the high voltage battery pack from the rack to install onto the vehicle