Material Handling Systems

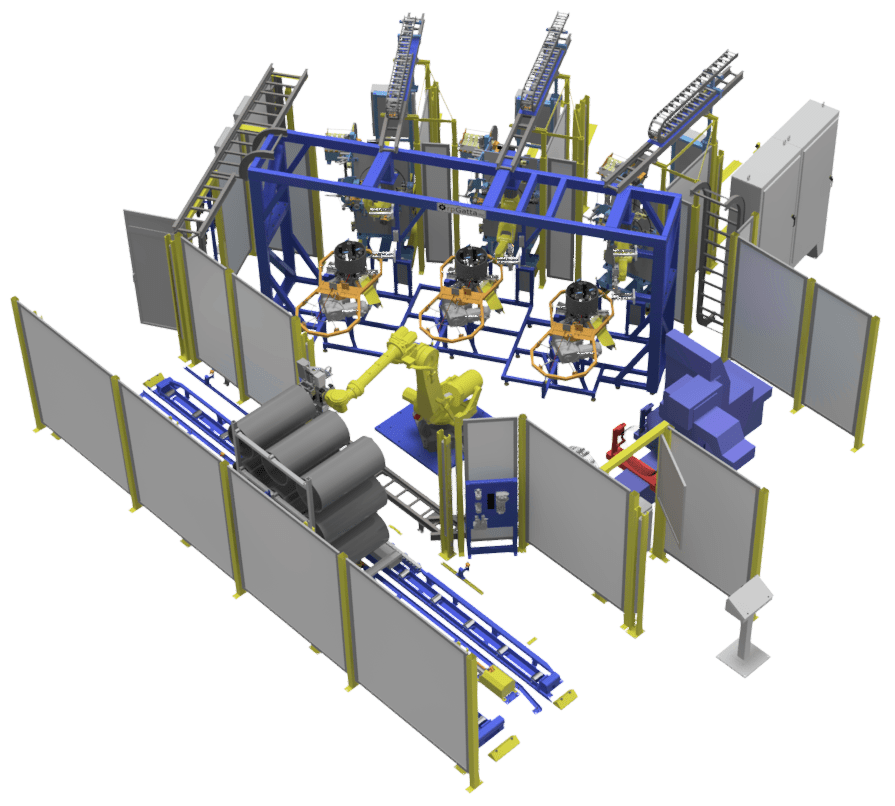

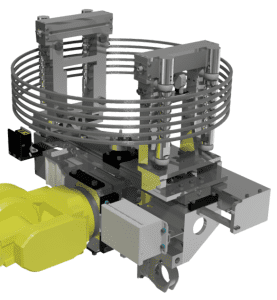

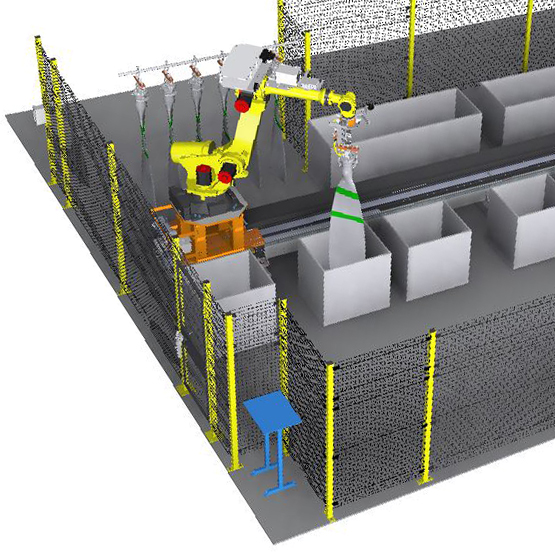

Automated Tire Bead Handling System

Features:

- (4) Fanuc Robots Total

- The R-2000 Robot transfers tire beads from a winding machine to custom hanging details on a custom overhead weldment

- The (3) LR-Mate Robots individually pick up the tire beads and load and unload them to and from (3) bead covering machines

- The R-2000 Robot loads stacks of beads onto a rack or cart using vision

- Custom rack/cart transfer system that handles either variant and automatically transfers them in and out of the system

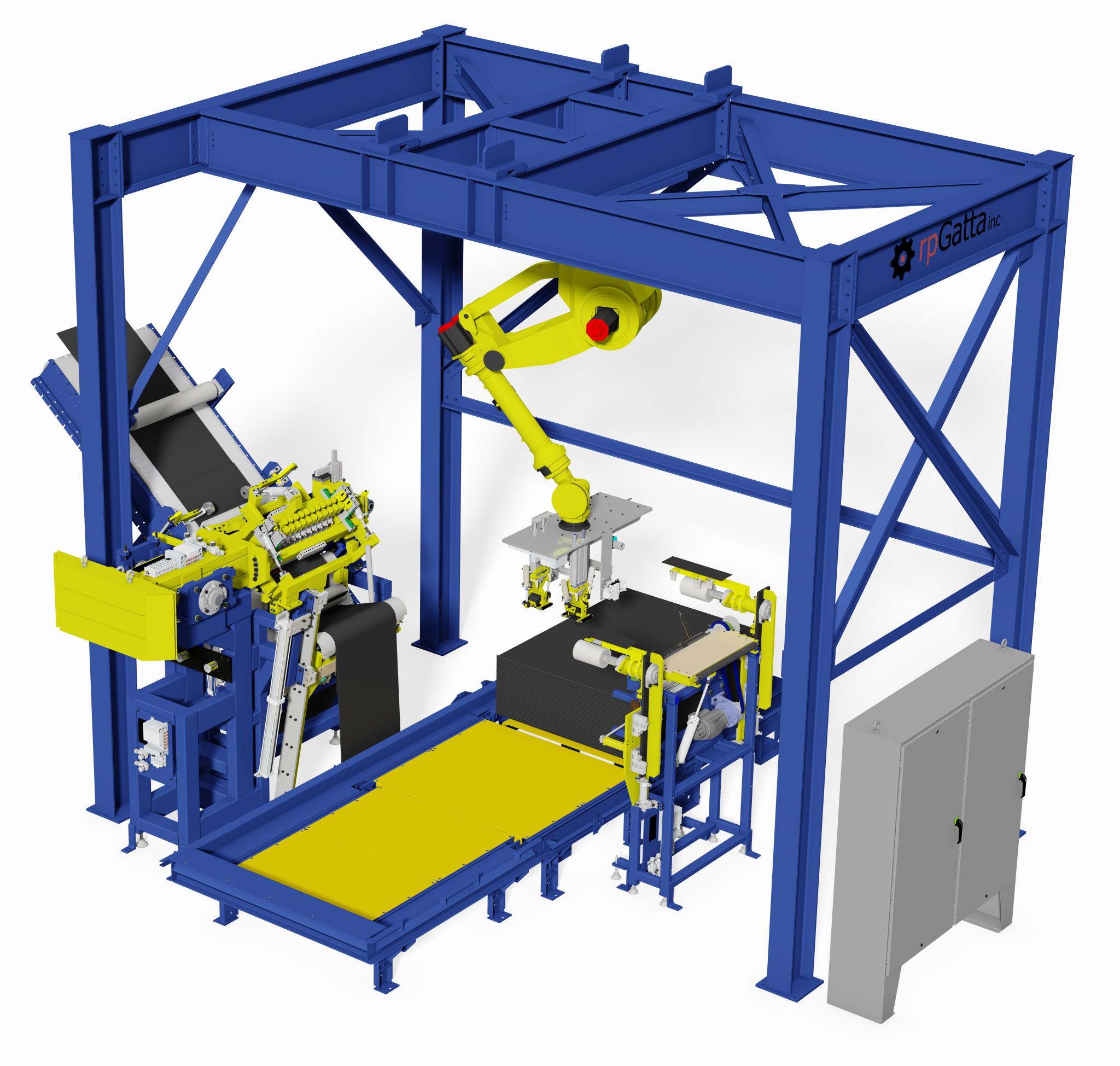

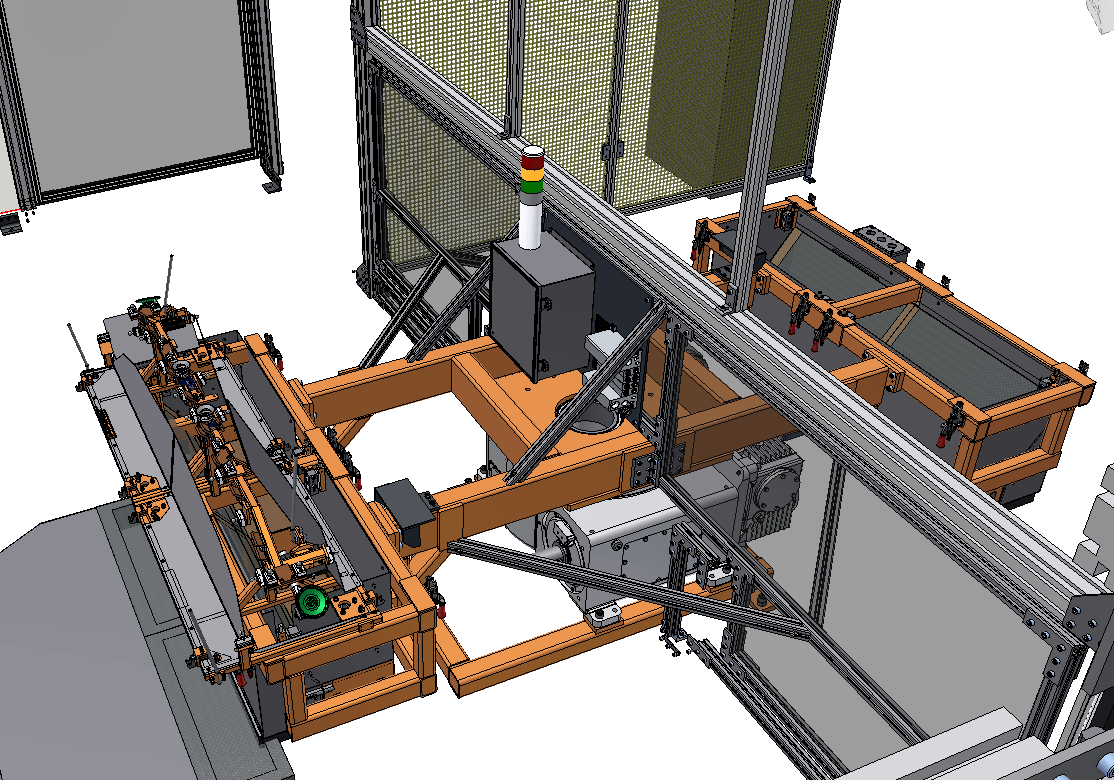

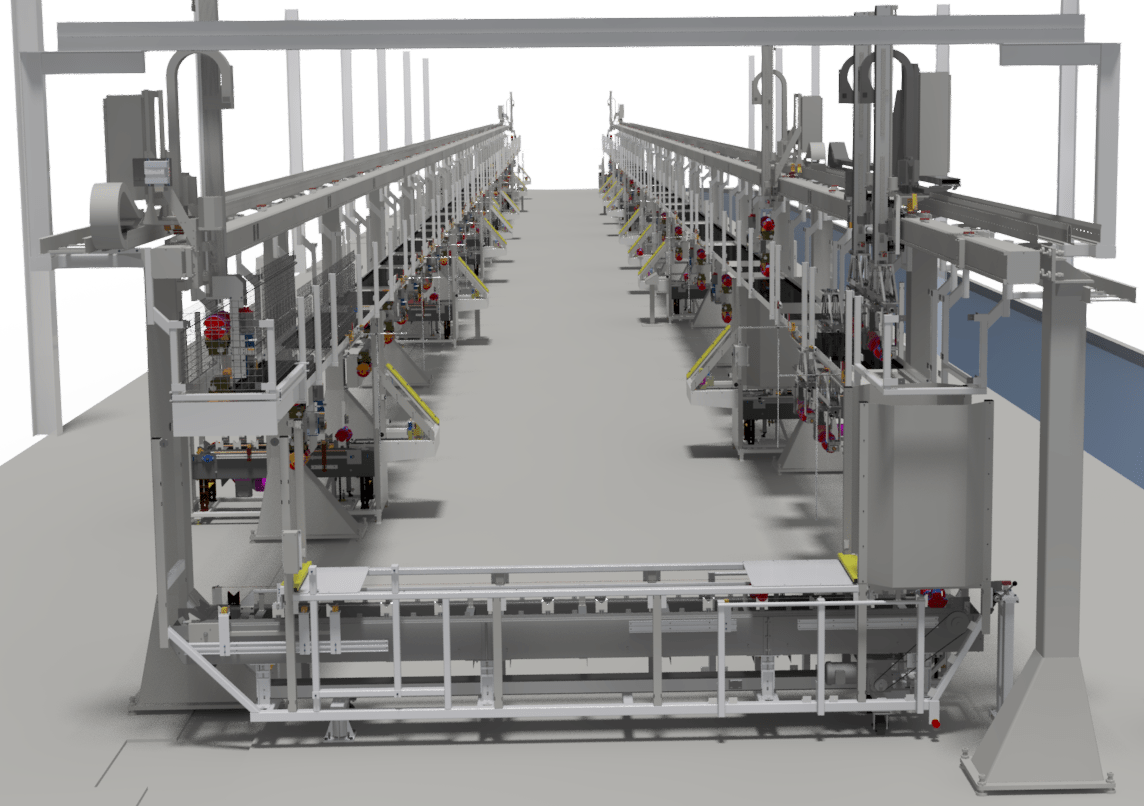

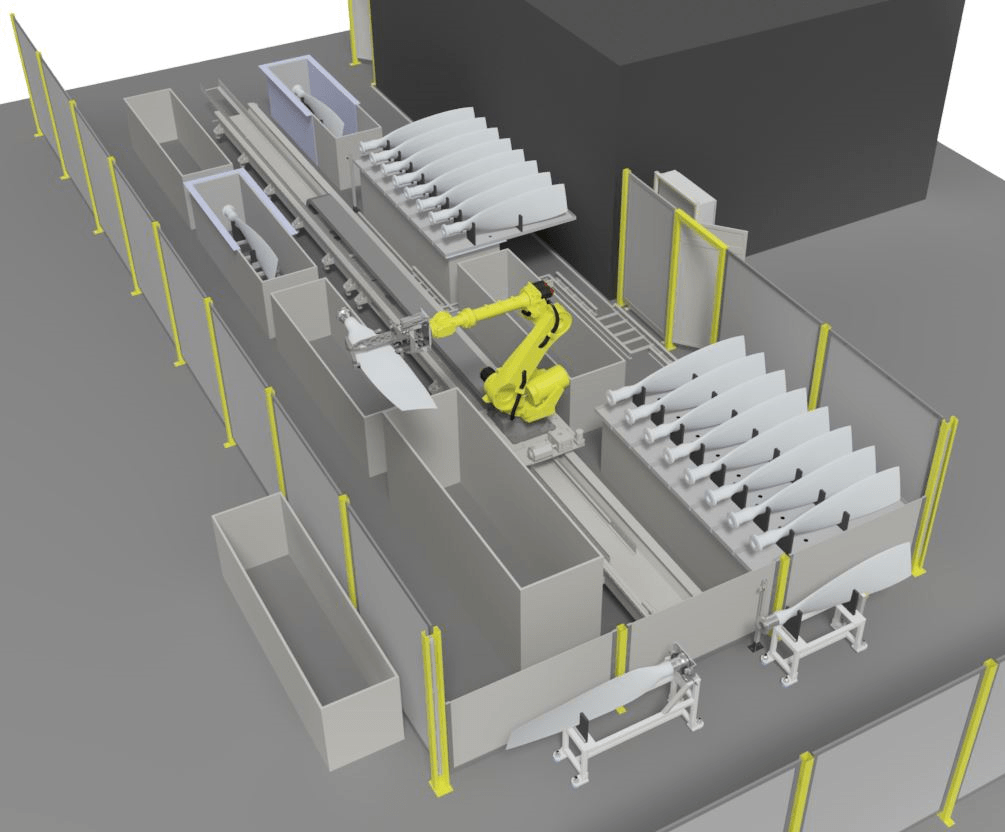

Robotic Rubber Slab Transfer System

Features:

- This system involves the material handling of rubber slabs which includes the custom design and integration of:

- 6-Axis Robot suspended from the underside of the gantry

- End Effector capable of locating and gripping the material

- Conveyor for the pallet indexing of the material

- Prep Station for the initial alignment of the material for the start of the cycle

- Feed-Stitcher for the automated process of stitching the material together

- Pallet Stacker for the loading of the material

- Safety Fence to ensure complete safety at all times during the cycle

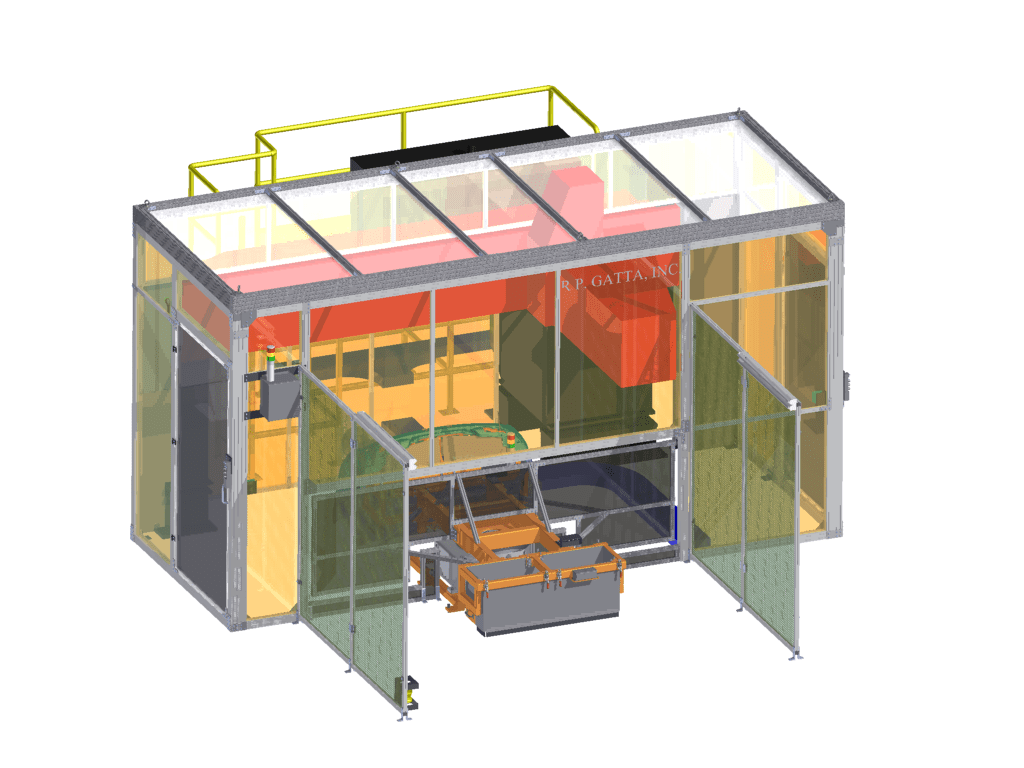

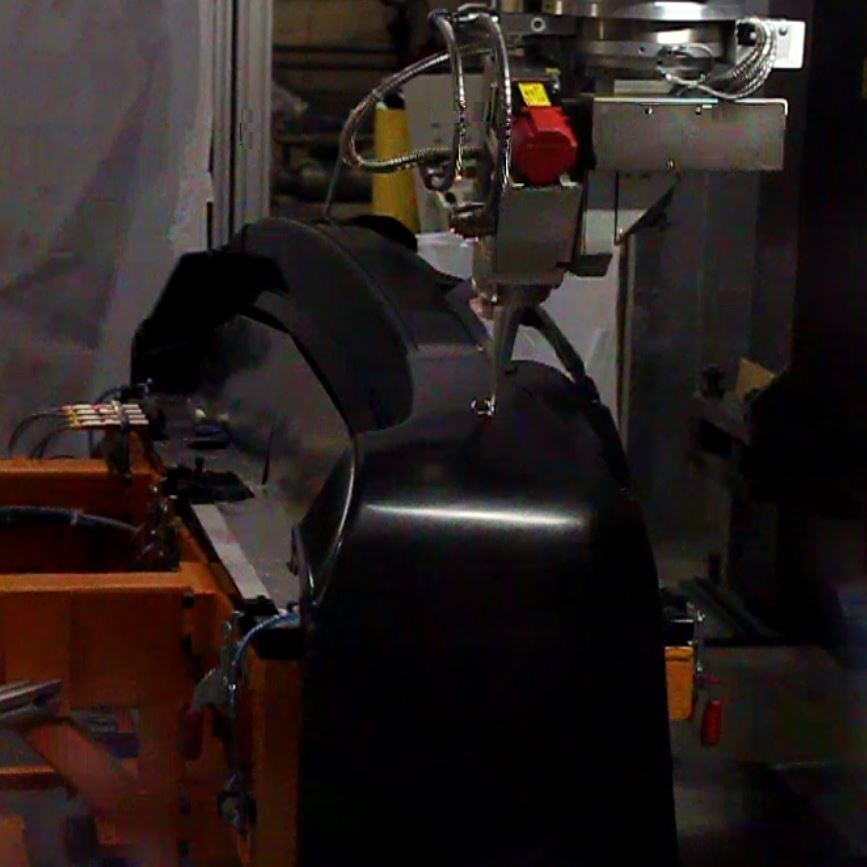

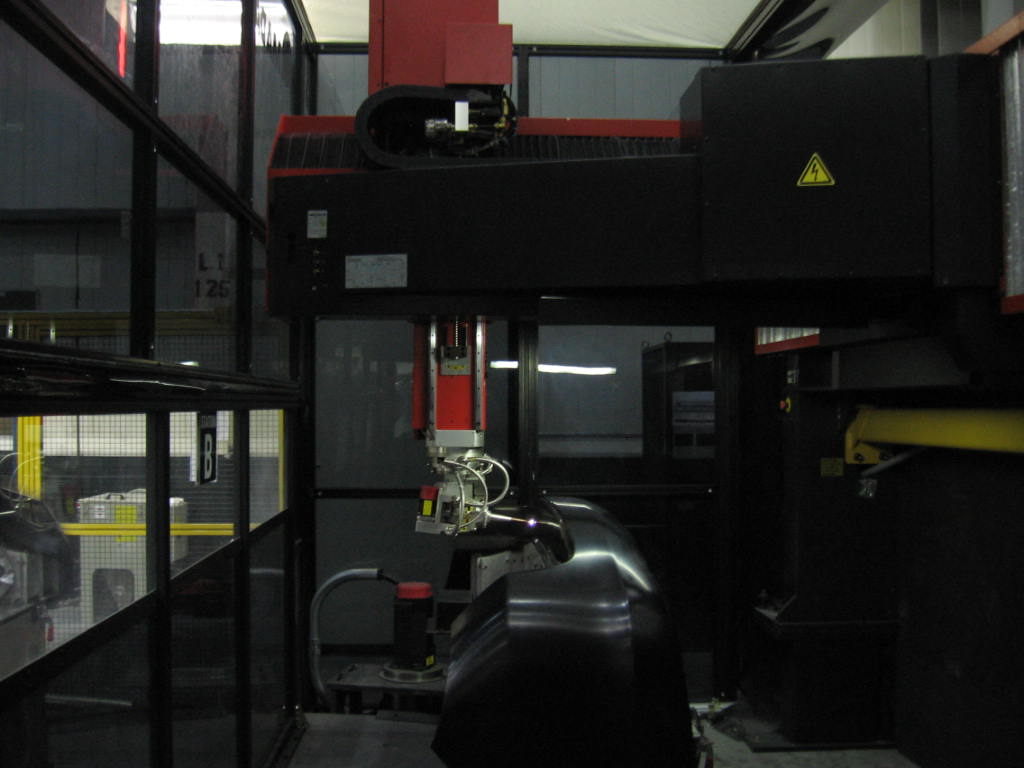

Bumper Fascia Laser Cutting CNC System

Features:

- Fixtured Turntable System for locating and feeding rear bumpers

- Flying Optic Laser System

- Laser Cutting System Enclosure with multiple other safety features

- System does not require the floor to rotate as most do

Weld Inspection Lift Stations

Features:

- Consists of air operated lifting masts set to the side of the vehicle

- Lifting arms will cantilever underneath the pallet and lift the pallet and vehicle

- The placement of the Lifting Masts under the rocker flange along one side of the conveyor allows for 24-27in of vertical lift

- Pushbutton controls allow the operator to raise and lower the system

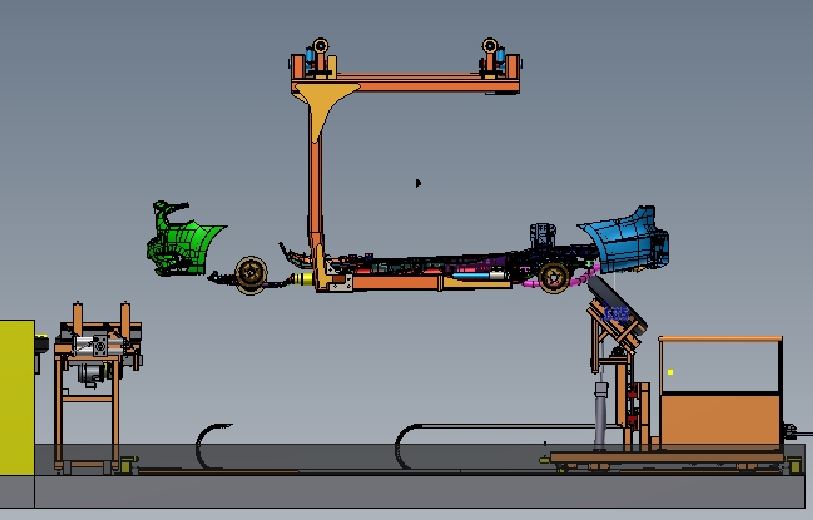

Spare Tire Rollover Systems

Features:

- VFD controlled synchronous carrier tracks along with the vehicle

- Automatically loads, rolls over, and lifts spare tires under the vehicle

- Lift arm for mounting torque tool

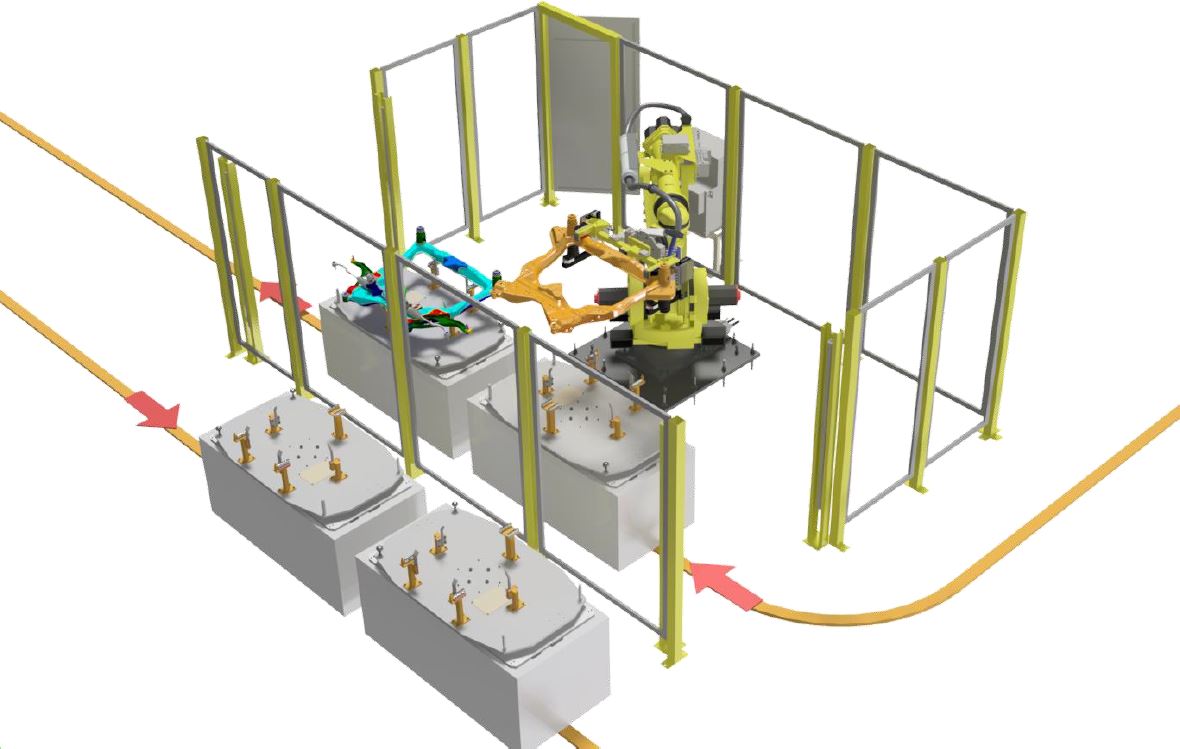

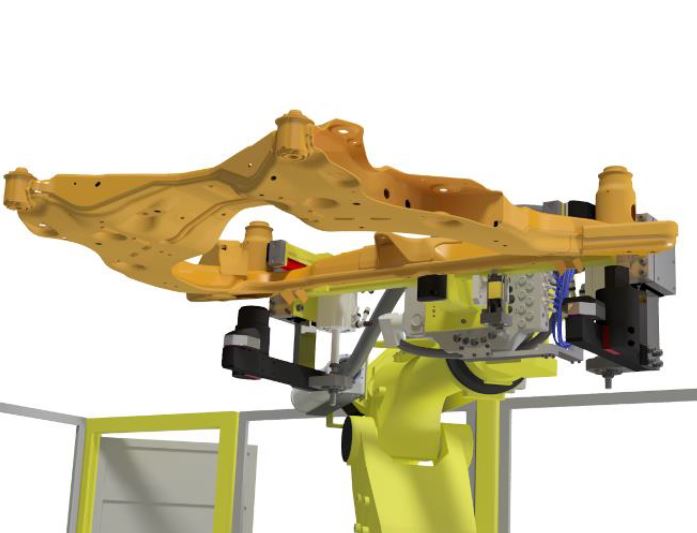

RSM Frame Transfer System

Features:

- Robot to automatically pick RSM frames from AGVs utilizing 3D vision and place them onto a prep table

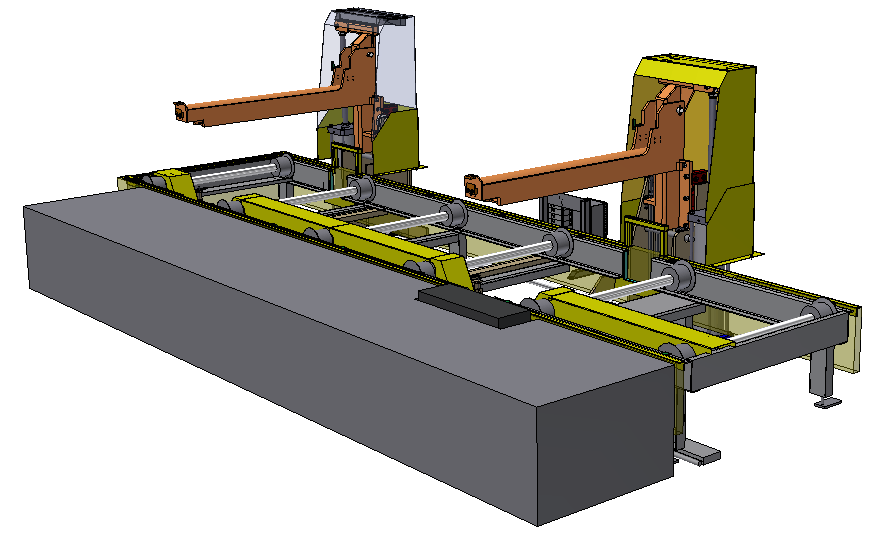

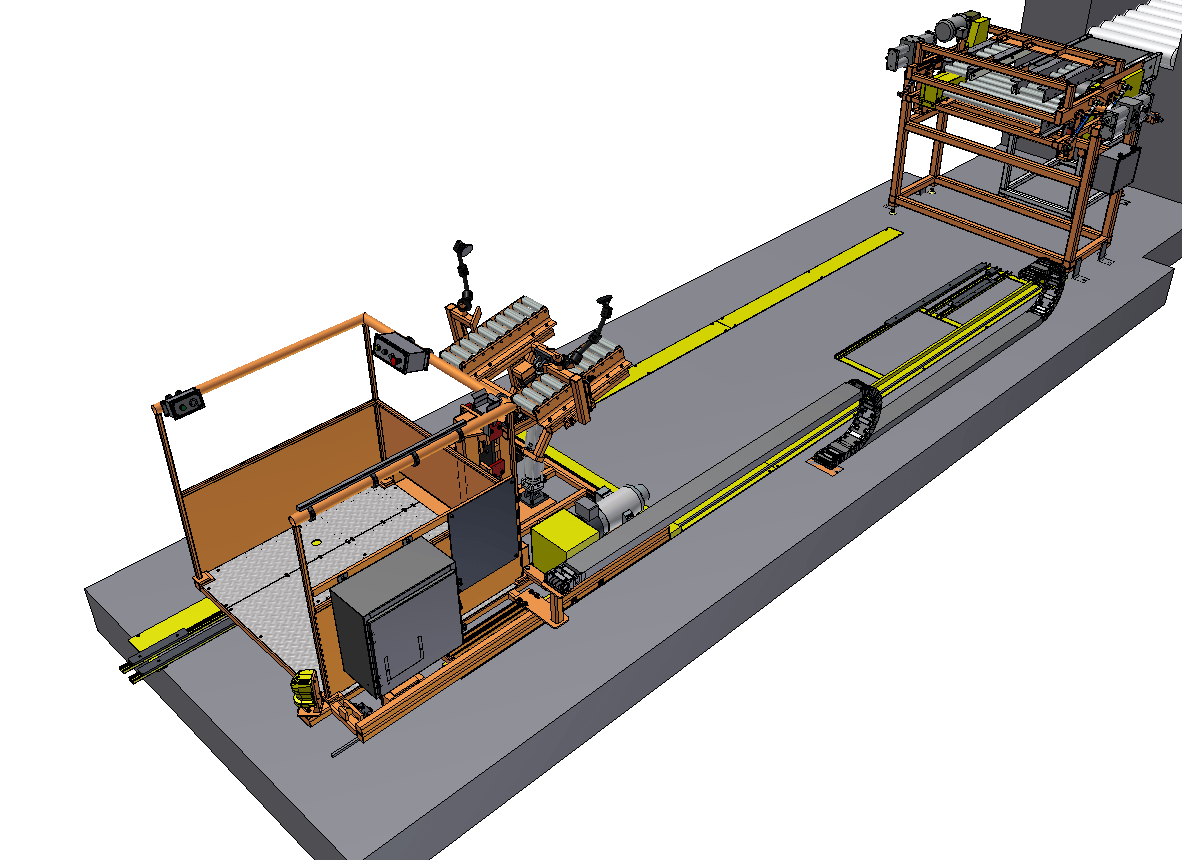

Crankshaft Material Handling Gantry

Features:

- 650 Foot Long 17 axis Servo Gantry Crankshaft Loading System

- 14-Crankshaft Loading, Buffer, Crossover and Unload Conveyors

- Multiple Quality Control Takeout Stations

- 17 Operator HMIs

- Integration of dozens of unique machines including bar code marking, data, and part tracking through grinders, lathes, balancers, hardeners, washers, gauges, mills, laser markers, conveyors, etc.

Check out this this Youtube video we did with Fanuc on our Crankshaft Machining Center Servo Gantry Loading System.

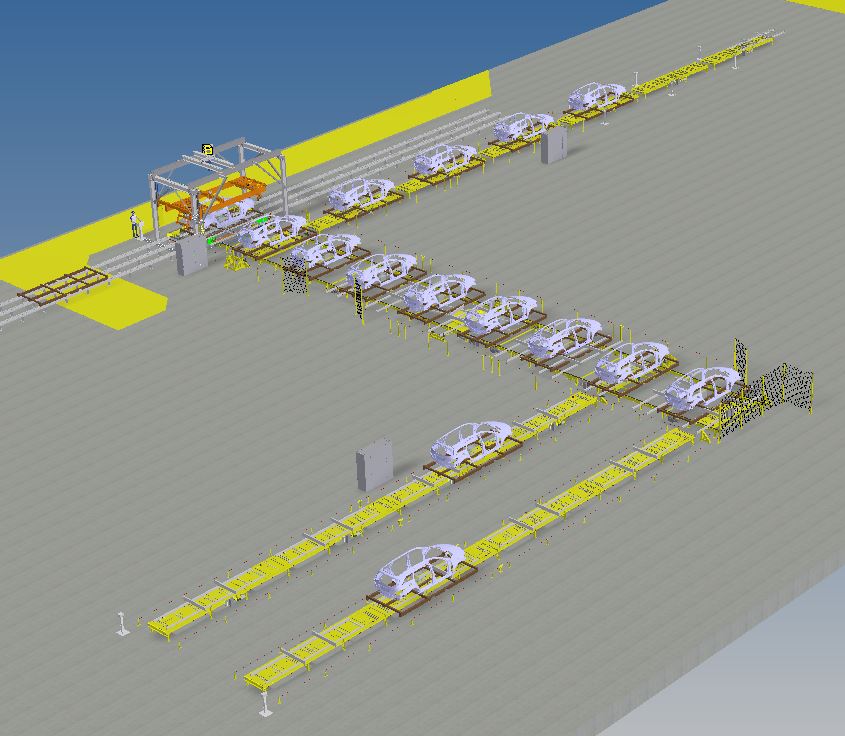

Vehicle Accumulation and Transfer Line

Features:

- Body Transfer System

- 470 Feet Of Driven Roller Conveyor

- Two-Strand Side Winders

- Vehicle Body Lift

- Skid Loading System

- Painted Body Load And Unload

- 2-Hydraulic Scissor Lifts

- Lift And Transfers Between Steel & Wood Skids

- Turntable To Rotate Skids 180°

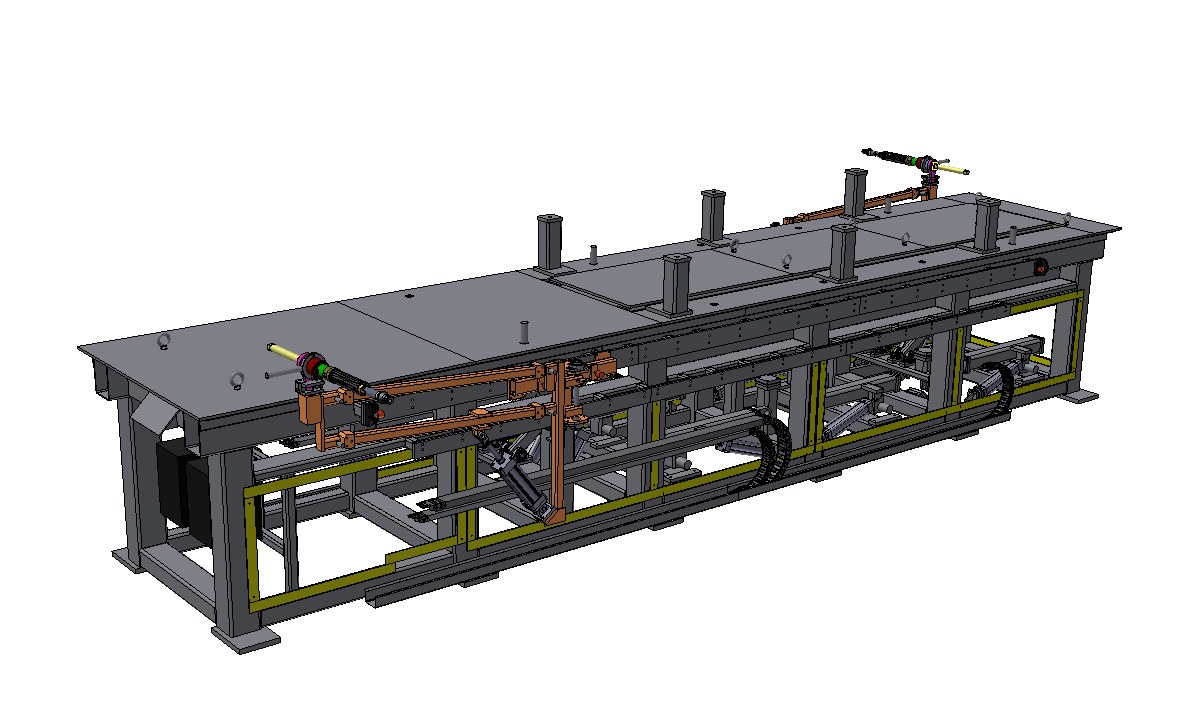

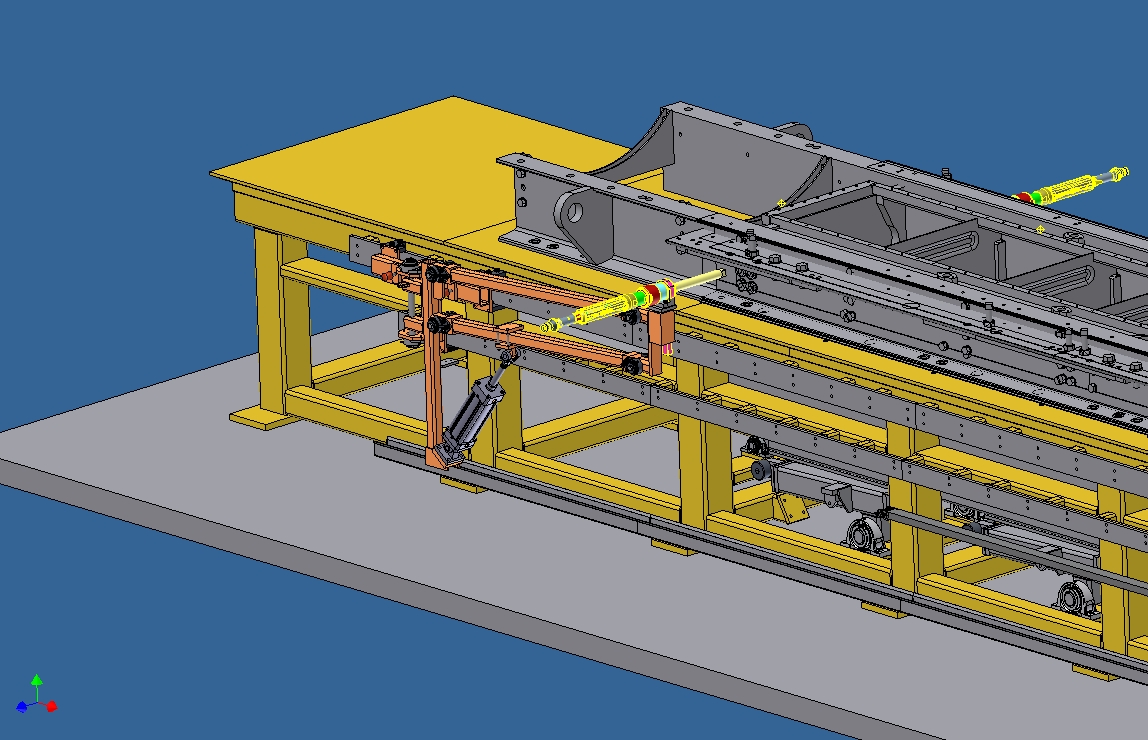

Rail Torque Tube Tables

Features:

- Custom 21′ LG Assembly Table Weldment

- Pneumatic height adjustment

- (2) Attached pneumatically balanced 4-bar linkage assemblies to mount manual torque tools

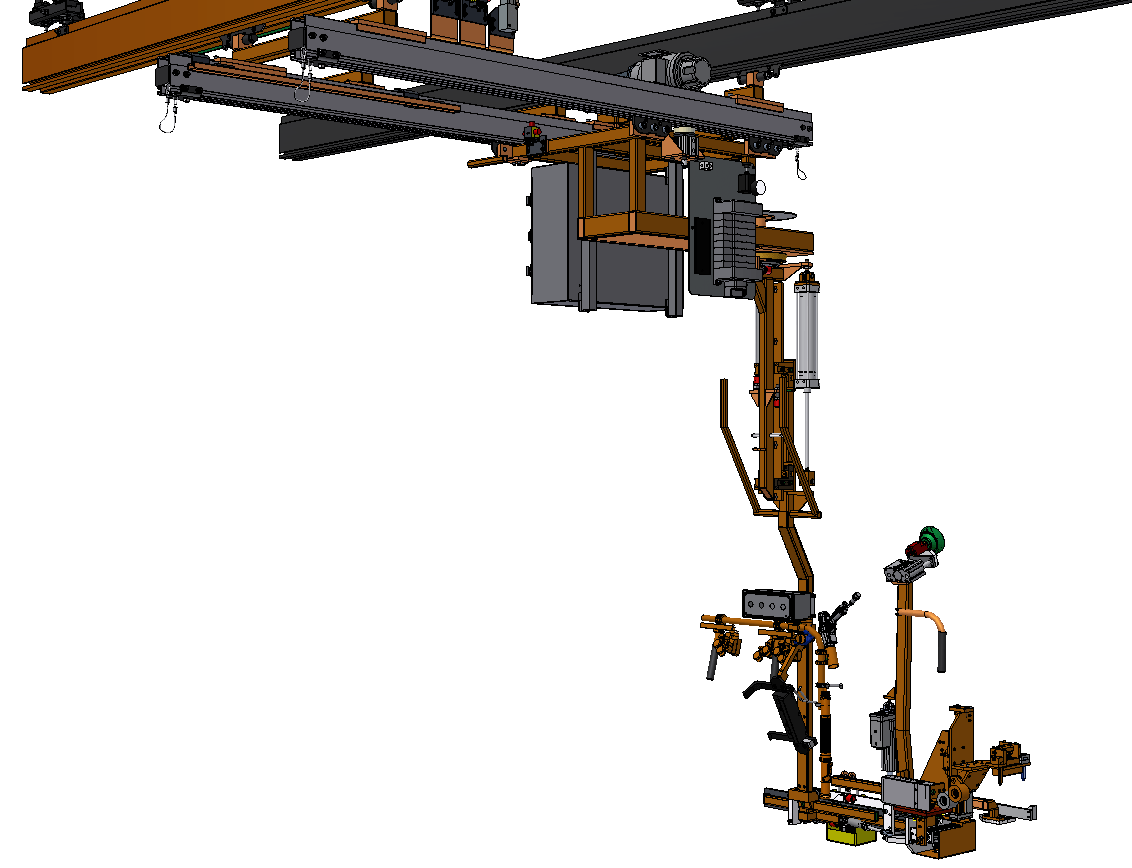

Sliding Door Assists

Features:

- Easily remove the doors from the door drop lifter and transfer to the vehicle body for installation

- Overhead mounted on dual runway and dual bridge rail system

- Assist’s weight and size is minimized to maximize the ergonomic benefits of the assists for the technicians

- Pneumatically actuated brake to allow operator to lock assist into position

Robotic Propeller Handling System

Robotic Propeller Dip Tank System

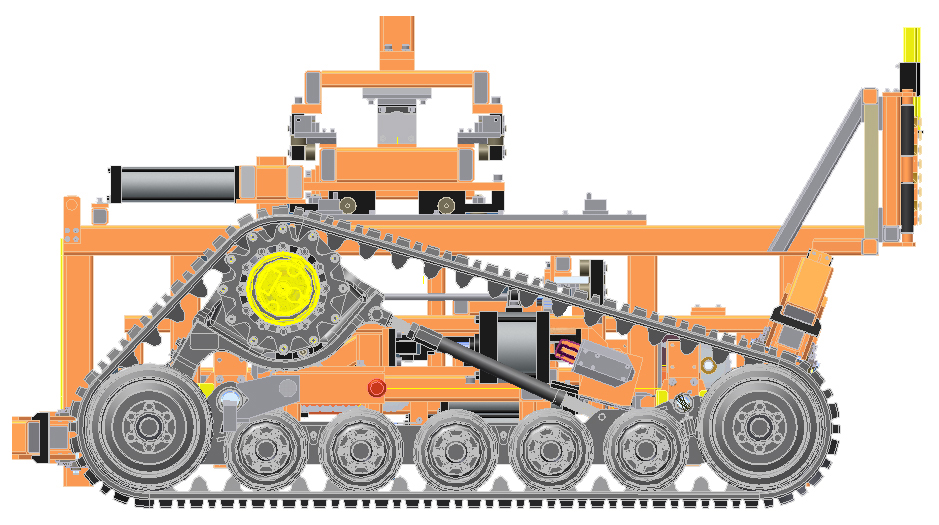

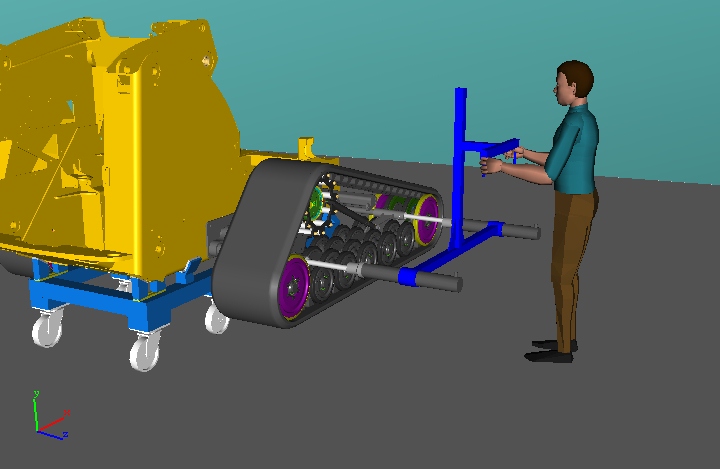

Track Press Fixture

Features:

- This operator-controlled assist picks and loads the RH and LH tracks onto steer skid loaders